If you’re not consciously monitoring process performance, you won’t notice when bottlenecks are blocking your pipelines.

Continuous process improvement (CPI) is the practice of continually tracking process performance to find inefficiencies and eradicate them.

But how do you establish a continuous improvement culture in your organization? And how do you know where to begin?

Read on to learn why continuous process improvement is so beneficial and how to get started with your CPI program.

Want to jump ahead? Click here:

- What’s Continuous Process Improvement?

- What Are the Benefits of Continuous Process Improvement?

- 4 Steps in the Process Improvement Cycle

- 6 Strategies for Continuous Process Improvement

- Need a Tool to Help with Continuous Process Improvement? Here’s What to Look For

What’s Continuous Process Improvement?

Continuous process improvement (CPI) is the practice of making incremental changes to your business processes to improve efficiency and quality.

Continuous process improvement is sometimes also known as ‘continual process improvement’. Not to be confused with business process reengineering (BPR), continual improvement invites you to make incremental changes to your processes rather than scrapping everything to completely redesign a new process.

This ongoing effort to improve existing business processes can consist of small changes that tweak the workflow or bigger ‘breakthrough’ improvements that encourage innovation.

Your CPI program should aim to boost efficiency, effectiveness, output quality, and flexibility. It’s a key component of achieving operational excellence.

Lots of organizations use workflow analysis software like frevvo to help with this process. Tools like this make it easy to track performance and spot areas for improvement.

What Are the Benefits of Continuous Process Improvement?

Continuous business process improvement aims to identify inefficiencies and bottlenecks and remove them to streamline workflows.

In doing this, you’ll experience a wealth of benefits, including:

- Reduced costs

- Faster processing

- Fewer errors

- Improved stakeholder and supplier relationships

- Better quality end products

- More productive employees

- Happier customers

The benefits you receive will depend on where you focus the improvement initiative.

For example, almost 70% of firms are currently concentrating their improvement efforts on boosting productivity and lowering costs. In addition, 38% are trying to increase customer satisfaction, and 35% are looking to improve existing products.

The outcomes will also depend on the existing process you choose to improve.

Look at Cricket Australia, for example.

The organization wanted to improve the processing speed of invoices, so they focused on improving their financial processes by switching to frevvo.

Now they can turn around invoices in half the time.

Prefer to see and hear it rather than read about it?

Let us show you how easy it is.

4 Steps in the Process Improvement Cycle

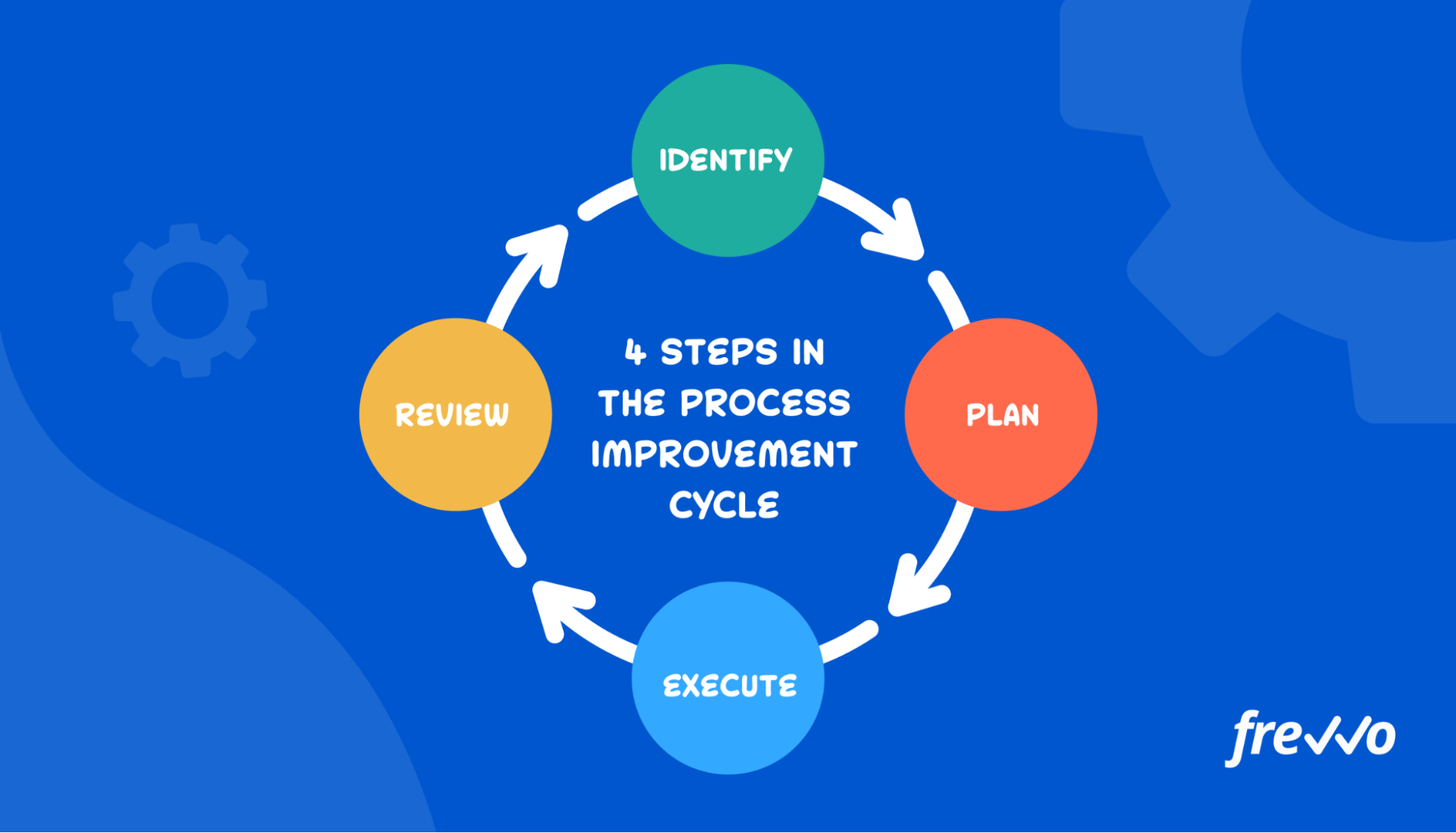

Most continuous improvement models contain four main steps. Following these steps will help you to analyze current problems, plan changes, and implement them incrementally.

Here are the four main process improvement steps to follow.

1. Identify Current Issues

To start, you’ll need to analyze the existing process to spot any bottlenecks clogging the workflow.

Process mapping will show you each step of the workflow so you can identify any unnecessary tasks that are holding it up.

Benchmark your current performance so that you can compare this data against any change you make.

2. Plan Improvements

Next, you’ll devise a plan for your process improvements.

If you’re only making small improvements, you’ll create a solution that tweaks the existing workflow.

If you’re planning a larger change, you’ll need to consider how you’ll take the current process offline without causing too much of a knock-on effect to other processes.

Plan both the improvement methodology and how you’ll scale the improvements once they’ve proved successful.

Remember to prioritize enhancements based on the impact they’ll have, as well as your available time, budget, and resources.

3. Execute Changes

When executing a process improvement, it’s wise to test it on a small scale first to see its impact. This prevents you from causing mammoth negative knock-on effects if your change isn’t planned correctly.

Once you’re sure the enhancement is functioning effectively, scale it up and roll it out across the organization.

4. Review Performance of Improvements

You need to track the performance of your changes to make sure they’re improving processes in the way you imagined they would.

Compare data to original benchmarks to see how well your solutions are performing. This will also help you to pinpoint the next incremental improvement to make.

Business process management (BPM) software like frevvo is ideal for tracking and measuring improvements over time.

6 Strategies for Continuous Process Improvement

There are several different methods to help you to analyze, plan, execute, and track ongoing improvement.

These tactics tend to tie in with different project management philosophies, meaning you can pick the model that fits with the way your team currently works.

Here are the top six strategies you can use to continually improve a process.

1. PDCA Cycle

This method is ideal for making incremental improvements to existing workflows.

The PDCA Cycle is a lean methodology, focusing on reducing unnecessary steps and wasteful procedures.

There are four steps:

- Plan: Once you’ve worked out where the inefficiencies are, make a plan to tackle each inefficiency.

- Do: Execute the adjustment on a small scale to see if it produces the results you’re looking for.

- Check: Check that the change is having the desired outcomes and is improving your process in the way you planned.

- Act: Scale up the process change before moving on to the next inefficiency.

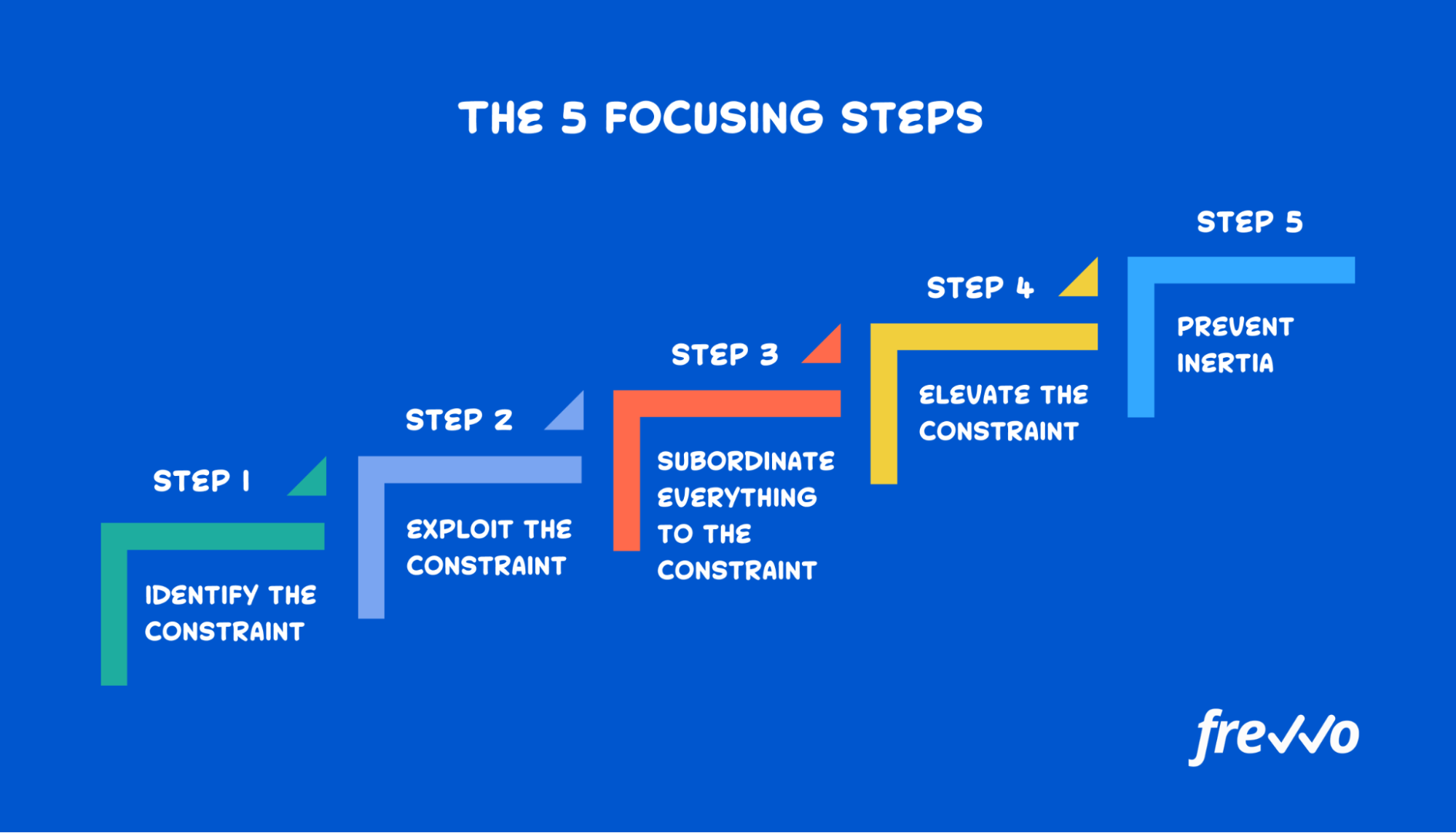

2. Five Focusing Steps

This improvement model is taken from the Theory of Constraints school of thought.

The idea is that you address the weakest link, repairing it until it is no longer the weakest link. Following this, you move on to the next weakest link.

Here’s how it works:

- Identify the constraint: Find the weakest link in your pipeline.

- Exploit the constraint: Push this element to the limit to see how much capacity you can get from it before increasing it — e.g., how many copies can you get from a copier in a given period before you need another machine to cope with the demand.

- Subordinate: Decrease the capacity of all other elements in the workflow to match the capacity of the weakest link.

- Elevate the constraint: Once you’ve exploited the constraint to its maximum capacity, add extras to increase the capacity at this stage.

- Prevent inertia: Keep continually improving by increasing the capacity of the non-constraints and addressing the element again or choosing the next weakest link.

3. DMAIC

This tactic is a Six Sigma method for planning and executing incremental improvements to current processes.

It’ll help you to work out the issue, benchmark current standards, plan changes, and analyze the results.

DMAIC stands for:

- Define: Define the goal of improving the current process so that you know where to focus enhancement efforts.

- Measure: Benchmark the current performance of the process.

- Analyze: Perform a root cause analysis to find out the main issue that’s preventing you from reaching your goal.

- Improve: Plan, test, and execute a solution to address this root cause.

- Control: Measure the performance of your solution to see if further improvement is needed.

4. BPM Lifecycle

The BPM lifecycle is a business process management technique that encourages a continual improvement cycle. Instead of keeping processes static, this method implies that there’s always room for adjustment to enhance workflow performance.

There are five steps:

- Analyze: Dig into the current process to identify areas for improvement and prioritize these changes based on their impacts and the resources you have.

- (Re)Design: Design changes to the process or redesign the workflow in its entirety. Many companies are introducing business process automation (BPA) software to streamline processes at this stage.

- Execute: Test the new solution on a small scale to see if it results in the outcomes you planned.

- Monitor: Track the performance of the process to see if the improvement is enhancing the process in the ways you’d like.

- Optimize: Optimize the change before rolling it out on a company-wide scale.

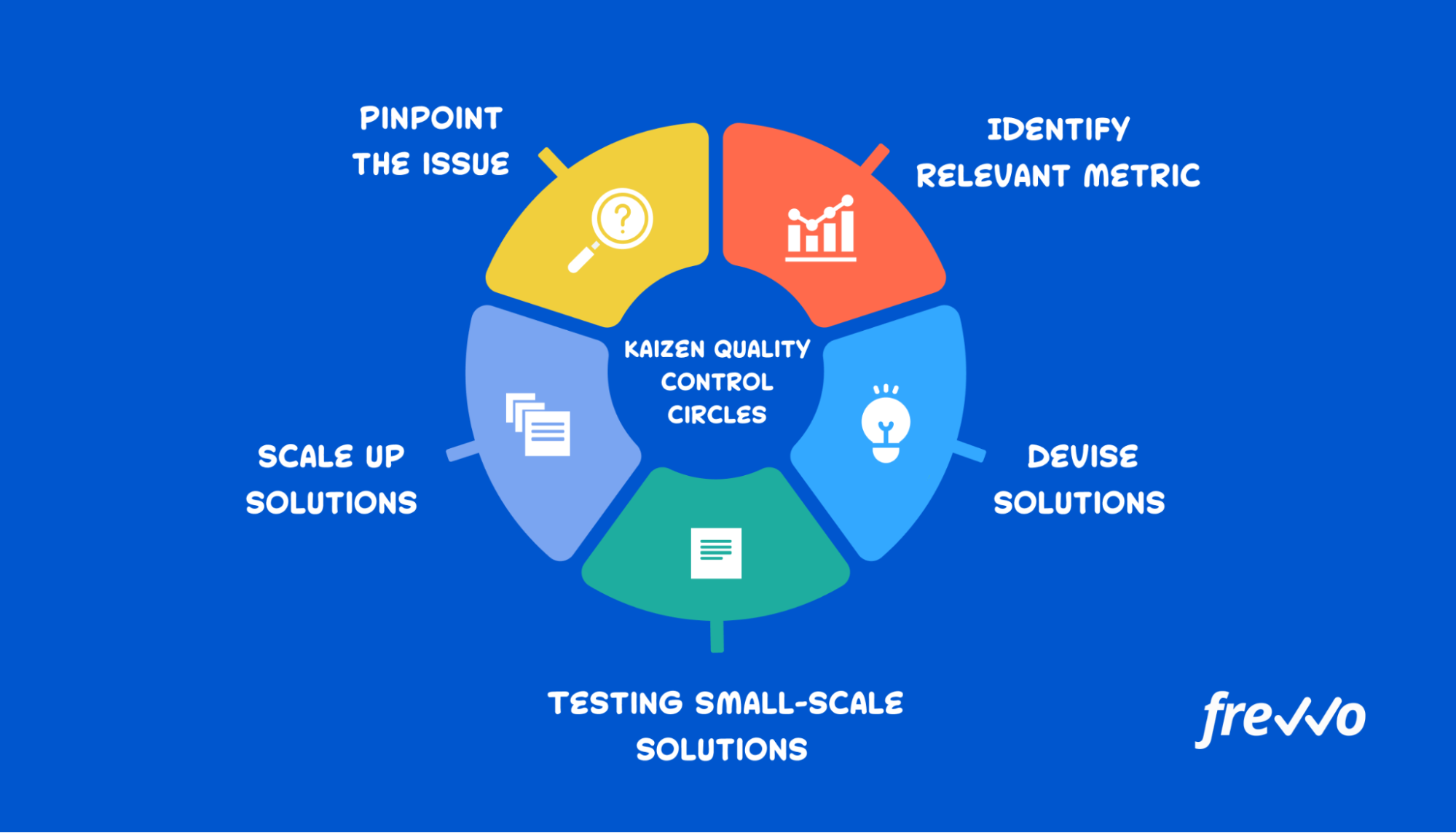

5. Kaizen Quality Control Circles

Kaizen is a methodology that encourages constant improvement. It is a Japanese term — ‘Kai’ means change, and ‘Zen’ means better.

The Kaizen philosophy encourages employee involvement when suggesting process improvements. A Kaizen Quality Control Circle is the technique used to plan and implement these suggested changes.

A small team of process improvement experts does the following:

- Identify the problem

- Define metrics to measure performance

- Create solutions to the issue

- Test solutions on a small scale

- Scale up solutions

6. The 5S Philosophy

The 5S philosophy is another lean methodology for making constant process enhancements.

The idea behind this tactic is to organize your workflows to promote greater efficiency, functionality, and higher levels of production.

The five parts of this philosophy are:

- Sort: Start by going through a process to work out where there are unnecessary or overly complex steps.

- Set in order: Create order within the process to make sure every step follows on logically from the last.

- Shine: Upgrade the process so that it performs better and more efficiently.

- Standardize: Create a consistent method in which the new process should be completed.

- Sustain: Train staff and track performance to sustain the improvements over time.

Need a Tool to Help with Continuous Process Improvement? Here’s What to Look For

Process improvement tools can help you to plan, implement, and track process changes more easily.

While there are no specific continuous process improvement tools, business process management software with the following features can help you enormously.

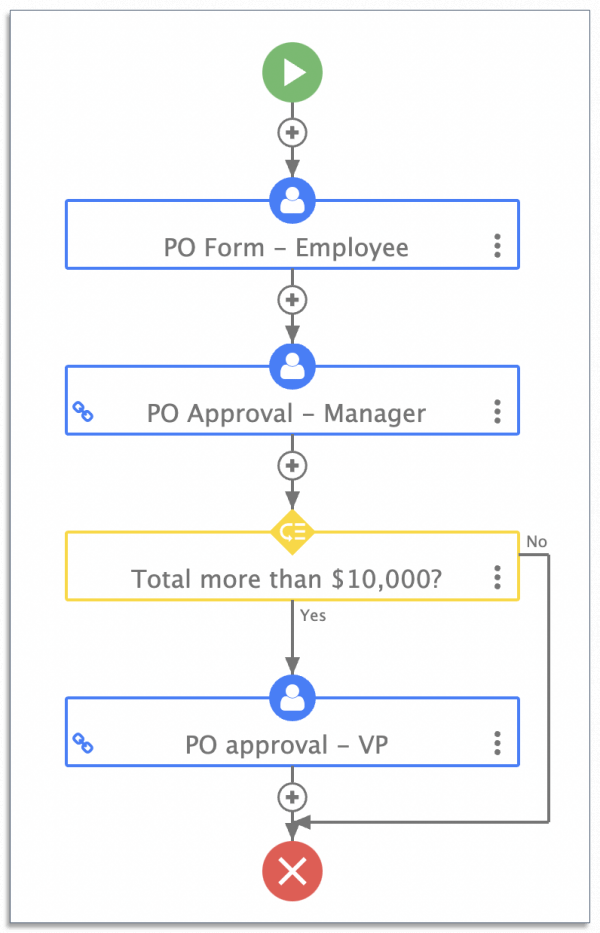

1. Mapping Functionality

Tools with process mapping functionality can help you create a visual representation of your workflows so you can see how current processes play out.

That way, you can spot unnecessary and inefficient steps, as well as more clearly see how and where enhancements would work best. For example, you may decide to add a condition so that POs don’t need to wait for VP approval if they’re under $10,000.

Good mapping tools enable you to assign roles to each step and let you explore conditional routes to understand how processes play out under different circumstances.

2. Straightforward Implementation Processes

A Continuous Process Improvement platform should be straightforward to set up and easy to use. If your staff needs a lot of training to get the hang of the tool, you’ll spend a lot of time and money before any process changes go ahead.

Instead, pick a software that’s intuitive to use and includes its own training resources.

Choose a low-code or no-code software. A platform that requires extensive coding limits the employees that can make process changes.

3. Automation Features

99% of business leaders agree that there are huge benefits to automation because it’s an effective way to speed up workflows, cut out errors, and reduce processing costs.

Look for a BPA software like frevvo that makes it easy to create digital forms and dynamically route them automatically through your workflows.

Make sure the software you pick has the capacity to auto-populate forms in order to reduce data entry, as well as the ability to validate forms automatically in order to eliminate data entry errors.

Automated notifications will prevent delays in the system, while automatic record-keeping keeps your audit trail up to date.

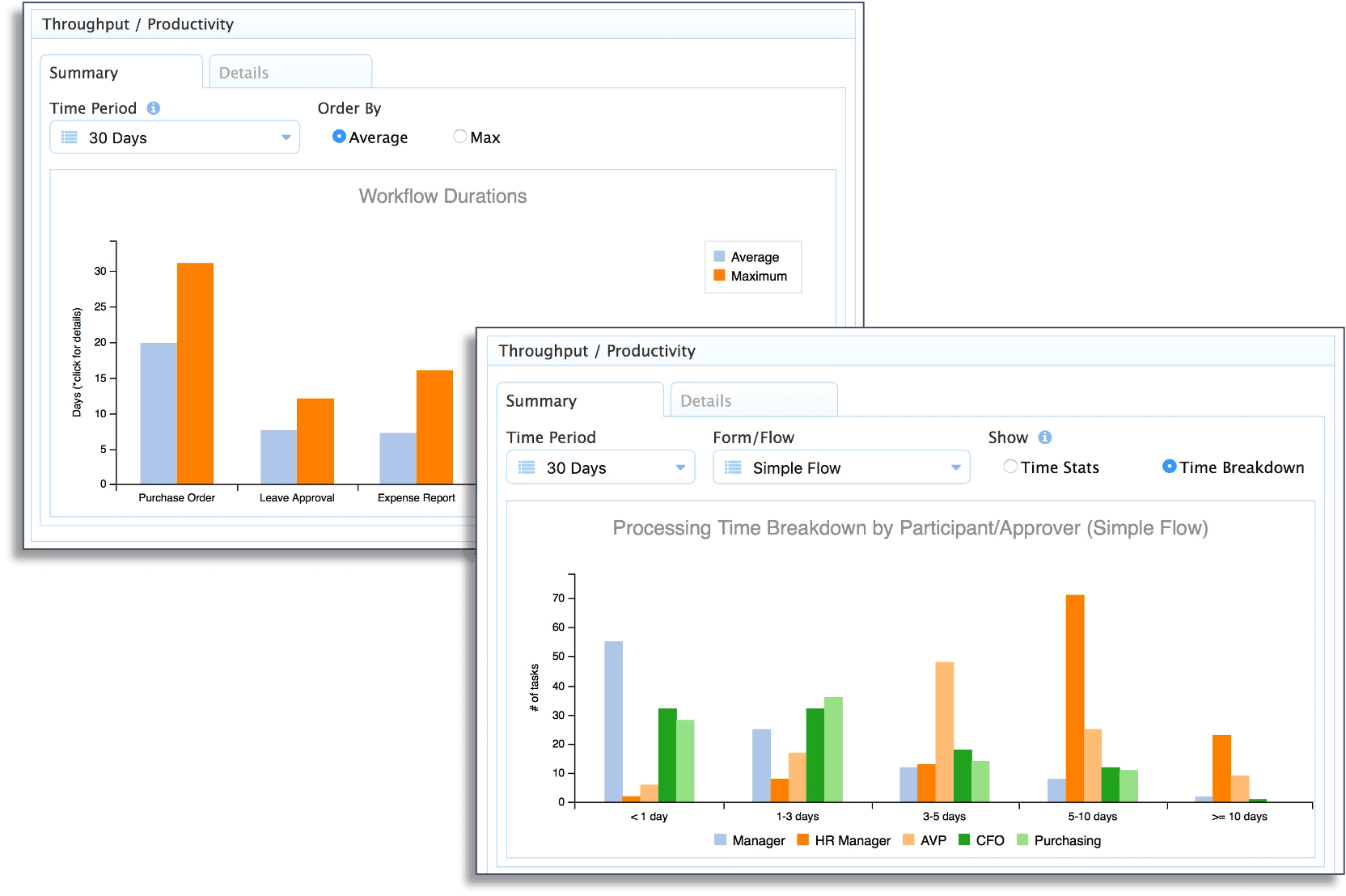

4. Performance Analysis Dashboard

You’ll need to track the performance of your workflows after you’ve made process adjustments.

That way, you’ll be able to see how well your processes have improved, whether they still need improvement, and whether there are any unplanned knock-on effects.

Choose a BPM software with a comprehensive analytics dashboard that makes it easy to automatically track performance by presenting it in a simple-to-digest manner.

Get Started with Continuous Process Improvement Now

Don’t let your processes stagnate. If you want to make sure you’re getting the best possible performance from your processes, you need to continuously improve your workflows.

There are many different improvement strategies you can use to streamline your processes, so find one that fits with the way your team currently operates.

Remember, one of the most effective ways to boost process efficiency is to scrap manual processing and replace it with automation. Try frevvo’s free trial today to experience the benefits yourself.