Your process is only as strong as its weakest link.

However, without a solid process improvement methodology to give you the framework to analyze and improve processes properly, you can’t be sure you’re always fixing the weakest link in the chain.

Read on to learn more about the top enhancement frameworks, how they work, and when to use them.

Want to jump ahead? Click here:

- Why is a Business Process Improvement Methodology Important?

- 5 Process Improvement Methodologies: Explained

Why is a Business Process Improvement Methodology Important?

A business process improvement (BPI) methodology provides a structure to help you make enhancements. It allows you to easily spot improvement opportunities and seamlessly roll out changes.

You’ll find that most process improvement methodologies give you a framework to analyze the issues, make small changes, and track improvements. That way, you have greater assurance that your alterations will do the trick before scaling them up to your entire organization.

When analyzing your workflows, you could find that several enhancements may bring positive change. However, you may not have the resources to implement all these changes simultaneously. By using a BPI methodology, you can more easily prioritize your improvements.

The benefit of having so many different methodologies to choose from is that you can find a framework that best suits the process you’re attempting to improve and fits into the way your project team operates already.

While it’s not impossible to implement process changes without a solid methodology, it’s not a good idea.

Unstructured process improvement projects aren’t particularly efficient. Since you’re not using a methodical practice to pinpoint inefficiencies, it can be challenging to properly prioritize the changes that will make the most impact.

This can lead to wasted resources. Plowing time, money, and effort into changes that have little impact can result in a failure to improve the process and a lack of resources to make any more changes.

Plus, it’s more challenging to get the whole team on the same page as your process change steps are less clear. If your team isn’t sure how they’re meant to be working the process differently, your improvement project is more likely to fail.

5 Process Improvement Methodologies: Explained

A well-designed process improvement plan can accelerate processing, cut out errors, reduce costs, strengthen stakeholder relationships, and enhance outputs.

Here are the top BPI methodologies for optimizing workflows to upgrade results.

1. Business Process Management

Business process management (BPM) is a methodology that helps you build new workflows, optimize current processes, and make continual improvements to your business systems.

The general idea behind this methodology is that optimization is a continuous process that should never be static. Once one refinement has been deployed to enhance process performance, you should be moving on to find the next tweak to enrich that workflow even more.

Analyze Process: Business Process Mapping

By creating a business process map for a new or current process, you can see where the bottlenecks are likely to occur, where you can make improvements, and how to prioritize those changes.

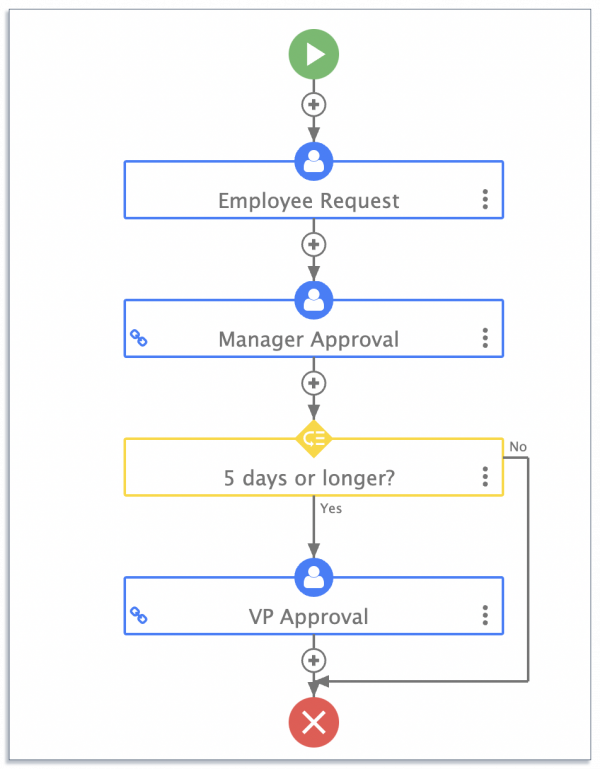

While you can map processes by hand, most organizations choose to employ BPM software. A tool like frevvo can help you map the flow of your processes to identify any unnecessary or inefficient steps.

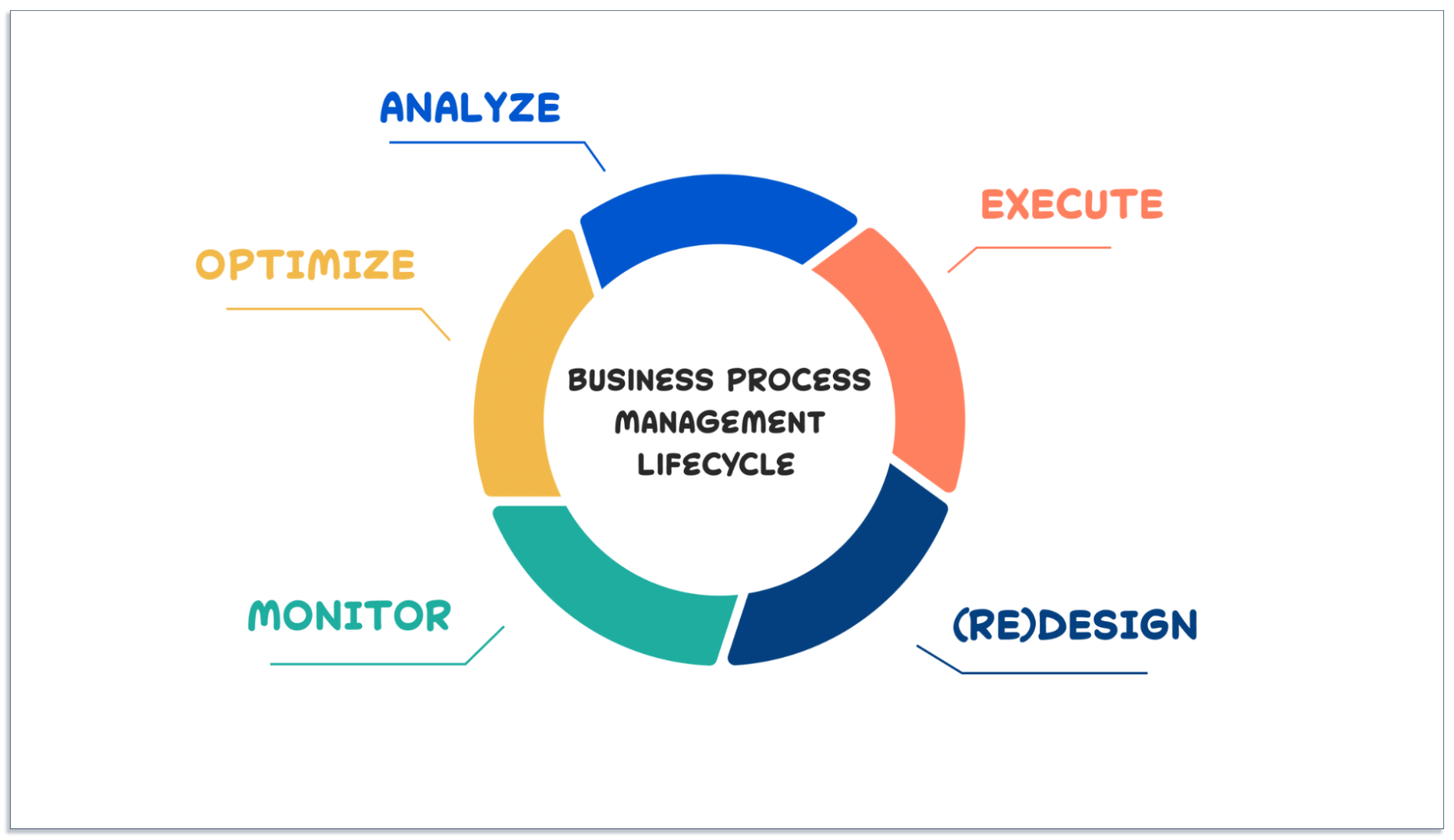

Continuous Process Improvement: BPM Lifecycle

The BPM lifecycle is a BPI method that provides a framework consisting of five stages to improve each workflow and reach optimization goals continually.

It includes the following steps:

- Analyze: Assess the current workflow to identify bottlenecks and spot areas for improvement. Prioritize changes by how easy they are to make and how much impact they’ll have.

- (Re)Design: Design process changes or redesign sections of the process depending on how bad the bottleneck is. Many organizations are introducing process automation solutions like frevvo to enhance workflows, with 27% of current automation initiatives specifically designed to optimize business processes.

- Execute: Implement the change on a small scale to test its effectiveness.

- Monitor: Keep track of key performance indicators (KPIs). A BPM software like frevvo is particularly useful for tracking KPIs automatically and presenting the data in an easy-to-understand dashboard.

- Optimize: Use the data to optimize the improvement before scaling it up.

Using this method, Cricket Australia could recognize the need to accelerate its invoicing process.

This led the company to implement frevvo’s business process automation software. In turn, Cricket Australia can now turn around invoices in half the time.

2. Six Sigma

The Six Sigma methodology is a widely implemented process management methodology used for various forms of manufacturing.

The underlying idea behind the Six Sigma methodology is to measure defects and inconsistencies to deliver perfect products and remove waste.

Waste is anything that doesn’t meet the customer experience. In this sense, improvements relate mostly to removing inconsistencies in the customer experience.

The Six Sigma improvement methodology is ideal for client-focused businesses looking to enhance the end product or experience.

Analyze Processes: 5 Why Analysis

The 5 Whys analysis tactic is a top tool to help you get to the bottom of the inefficiencies in your workflows. This helps you distinguish between symptoms of a problem and the root cause of the issue. That way, you can design improvements to address the root cause rather than simply treating a symptom.

The 5 Whys analysis is simple. You identify a bottleneck and then ask “why?” five times to dig into the root cause.

For example, imagine your customers keep complaining about late deliveries.

- Why are your deliveries late? There are too many products to deliver each day and not enough time for the delivery drivers to make each drop.

- Why don’t the delivery drivers have enough time? There aren’t enough delivery drivers to cover all the deliveries.

- Why aren’t there enough delivery drivers? Orders have increased, but no new drivers have been hired?

- Why haven’t any new drivers been hired? The HR department doesn’t have the capacity to vet and hire new drivers.

- Why doesn’t the HR department have time to hire new drivers? The HR department has focused on expanding the sales department to increase incoming revenue.

Looking at this issue, it’s clear that the HR department needs to switch its focus to hiring delivery drivers to deal with the increase of orders that resulted from expanding the sales department.

Improve Processes: DMAIC

If you’re looking to improve existing processes that affect customer-facing outputs, try the DMAIC method. This tactic helps identify and eradicate waste and inefficiencies, such as errors in the pipeline and excess processing costs.

- Define: Outline the goal of optimizing your process.

- Measure: Measure the current process to see how it’s performing.

- Analyze: Pinpoint the root issues that are hampering performance.

- Improve: Design and implement a solution that tackles the root problem.

- Control: Track the performance improvement initiative to make sure it’s working.

Build New Processes: DMADV

If you’re trying to build a new process into your organization or completely replace an outdated workflow, the DMADV method offers a succinct framework:

- Define: Specify the goal of creating the process.

- Measure: Define the critical-to-quality parameters (CTQs) and measure how well they are being met currently.

- Analyze: Assess existing issues and possible enhancements that can be made.

- Design: Design and implement the new process.

- Verify: Test performance to verify that the process improves the CTQs.

3. Lean Manufacturing

Lean process improvement comes from the lean principle of cutting out process waste that doesn’t add to value creation.

The lean thinking approach is particularly concerned with quality improvement and cost reduction to maximize outputs.

If you’re looking to improve the quality of your outputs while reducing processing costs that don’t tie back to revenue, consider the lean manufacturing framework.

Analyze Processes: 7 Types of Company Waste

By pinpointing waste in your pipeline, you can identify unnecessary or inefficient process steps. Using the seven types of company waste, you can better prioritize which step you’d like to improve first.

The seven types of company waste are:

- Transportation: Any excess costs or steps involved in the movement of goods, materials, or resources

- Inventory: Unused or unprocessed inventory, including costs tied up in unsold inventory and inventory damage.

- Motion: Referring to both people and equipment, waste motions are excessive actions used to do something that could be completed with fewer movements.

- Waiting: Time and costs associated with waiting, such as wasted labor hours where employees are waiting for other staff to finish a job.

- Overproduction: Waste associated with producing too many goods that can’t be sold and therefore need to be discarded.

- Overprocessing: Waste that comes from processing goods more than they need to be processed, such as painting a section of a product that won’t be seen.

- Defects: Waste that arises due to errors in the process.

One-Off Process Improvement: Deming Cycle (PDCA)

If you’re making a one-off improvement to a workflow, try using the PDCA framework. This helps you analyze issues, build solutions, test their efficacy, and scale them up.

- Plan: Find the problem, analyze the extent of the issue, and plan a solution.

- Do: Implement the solution on a small scale.

- Check: Track and measure performance to check the solution is improving the workflow.

- Act: Scale up the solution to fix the whole problem.

Continuous Process Improvement: Kaizen

The word ‘kaizen’ is a Japanese term that means to change (Kai) for the better (Zen).

Kaizen isn’t a solid framework but more of a philosophy that incorporates different improvement tactics to install a culture of continuous improvement within your team.

For example, Kaizen Corners are physical locations where staff can go to leave suggestions. Every suggestion is considered and evaluated, and where appropriate, staff are given feedback as to why their solution isn’t chosen.

One Kaizen method for building and testing solutions is to use Quality Control Circles.

Quality Control Circles comprise small teams of process improvement experts who work on enhancement solutions based on team suggestions. These groups work by:

- Pinpointing the problem

- Finding relevant metrics to measure performance

- Devising solutions

- Testing solutions on a small scale

- Rolling out scaled-up solutions

4. Agile

The Agile philosophy takes an iterative approach to project management and process improvement.

By treating workflow improvements like a project, the Agile philosophy invites you to use the Scrum framework to make enhancements to your processes and receive feedback on these implementations as you go.

This allows you to make fixes that address speed, budget, and quality while remaining flexible on the scope of improvements.

Continuous Process Improvement: Scrum

When planning improvements using the Scrum methodology, you need to create a backlog of changes that you intend to implement. Use the following framework to do this:

- Initiate improvements: Pinpoint the processes that you want to improve.

- Diagnose: Find the issues in your existing processes.

- Establish: Prioritize improvements and develop a plan to tackle each.

- Act: Develop solutions, pilot these changes, refine the implementations, and scale them up.

- Learn: Measure feedback, analyze performance, and use this data feed forward to improve enhancements.

The work for each enhancement should be done in short bursts of incremental work, known as Sprints. Each Sprint has a predetermined time frame before the team comes back to assess the work that’s been carried out to make any priority changes.

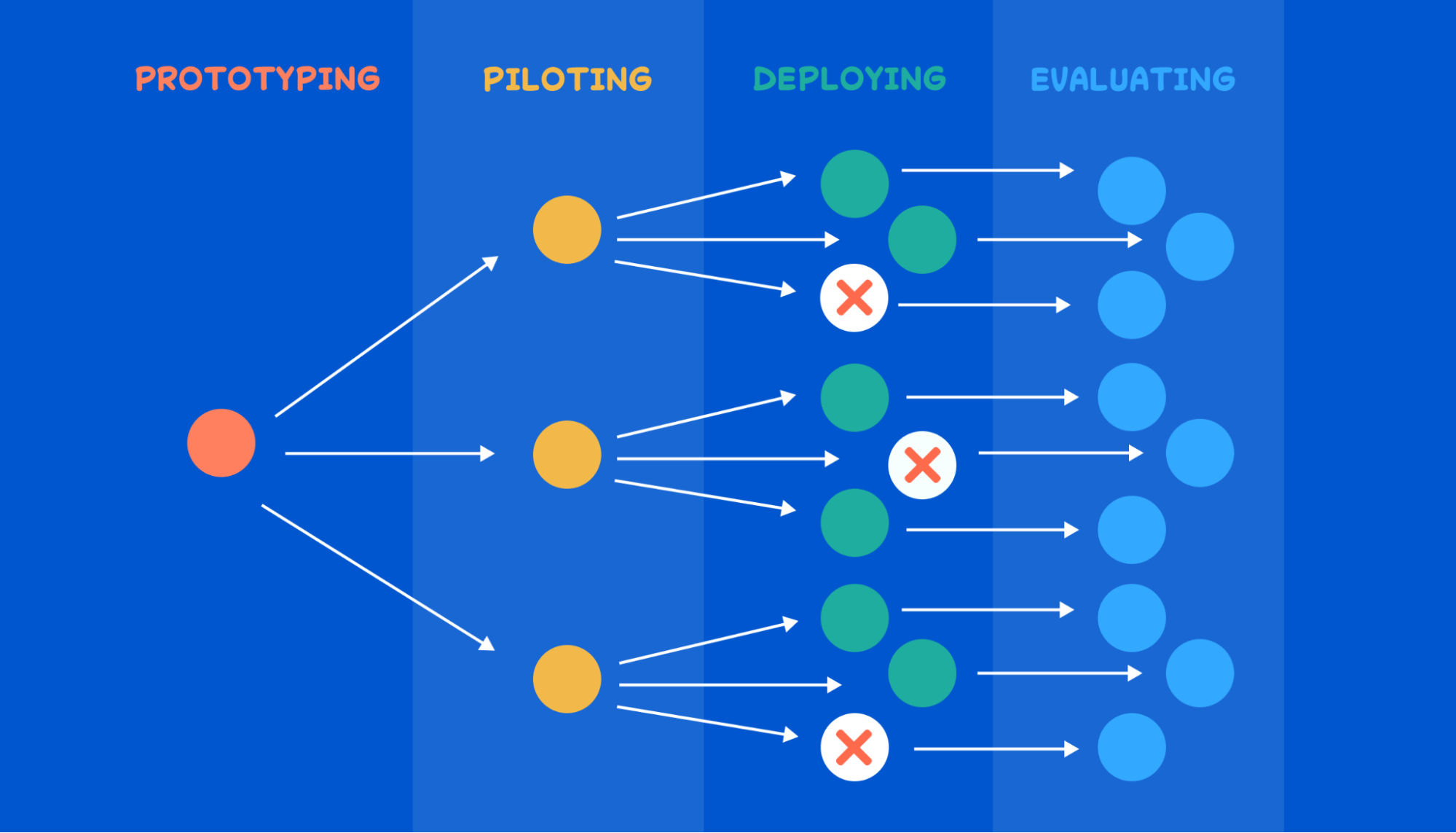

Once workflow improvements have been planned, it’s best to roll them out across four Sprints:

- Prototype: Make a small-scale change.

- Pilot: Test this small-scale change.

- Deploy: Scale up the change.

- Evaluate: Test the performance of the scaled-up change.

5. Theory of Constraints

Theory of Constraints makes improvements by addressing the biggest factor preventing you from reaching your goal.

This philosophy rests on the idea that you need to strengthen the weakest link in the chain. Strengthening other links won’t stop the weakest link from breaking, so you need to focus your energy on your biggest vulnerability.

Once you address this weak link, move on to the next weakest to systematically tackle all inefficiencies.

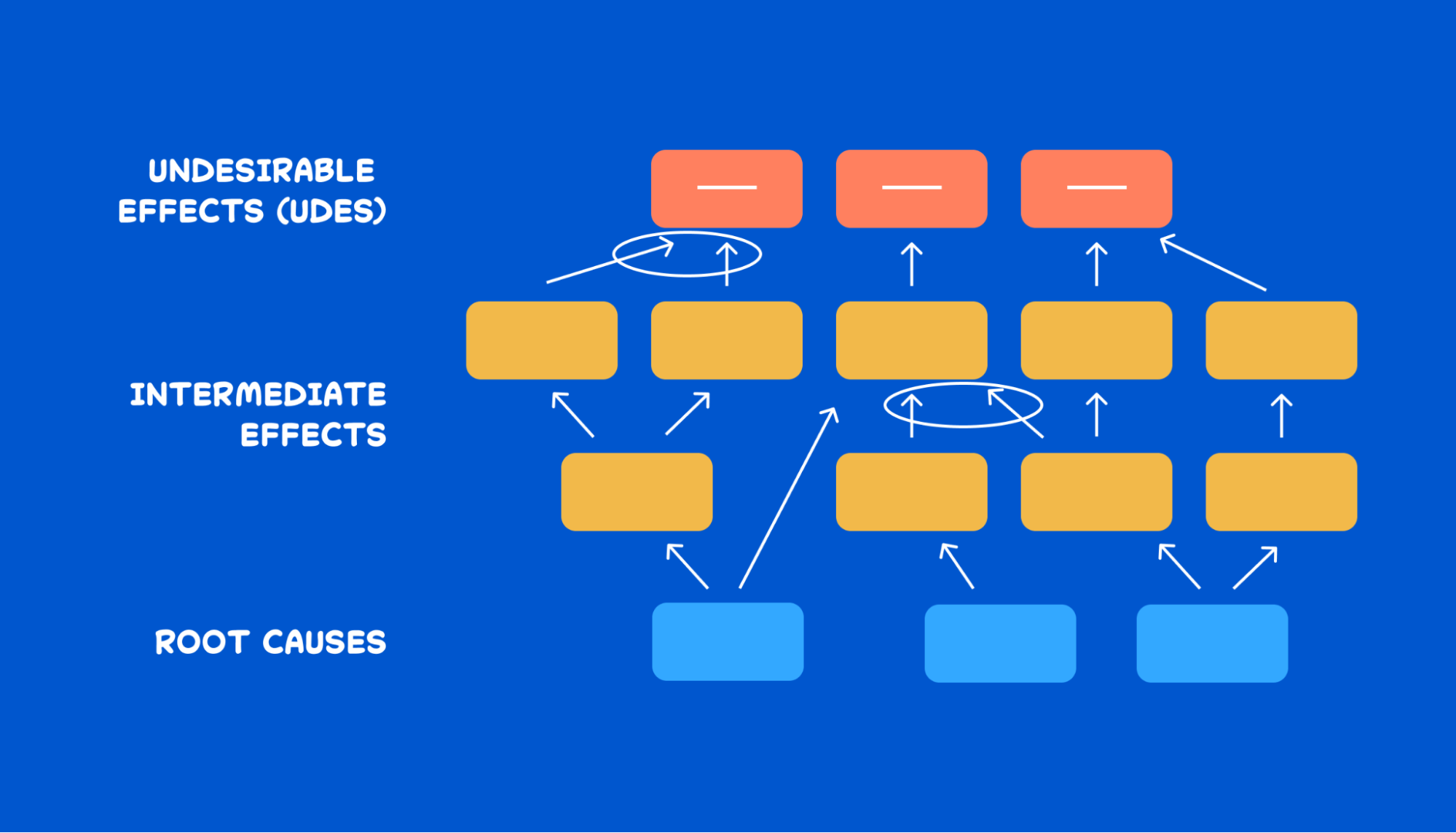

Process Analysis: Reality Tree Diagram

A Reality Tree diagram helps you trace back from a surface problem to discover its root cause.

List your negative results and then take steps backward as many times as you need, identifying undesirable intermediate effects. When you can’t think back any further, you’ve reached your root cause.

For example, you may have unhappy customers.

This may be due to late deliveries. Late deliveries are caused by incorrect paperwork. Incorrect paperwork is a result of poor staff training.

A lack of staff training is the root cause.

Continuous Process Improvement: Five Focusing Steps

To address the weakest links and continually make improvements to workflows, use the Five Focusing Steps technique:

- Identify the constraint: Find and prioritize the root cause that’s the weakest link.

- Exploit the constraint: How much capacity can you get out of this piece of equipment/person/practice before buying more machinery/hiring more people/increasing the practices?

- Subordinate: Reduce the capacity of everything else in the process as to not overload the constraint.

- Elevate the constraint: Once you’ve exploited the constraint to its maximum capacity, increase/buy more/add extra to increase the capacity.

- Prevent inertia: Either elevate non-constraints to make the weakest link the weakest again and start over or begin again at the new weakest link.

Conclusion

While several different process improvement methodologies are available, the one you choose will depend on the type of process improvement you’re trying to make and how your team is structured.

Whatever methodology you pick, your focus should be on removing waste in the pipeline to increase efficiency. Since manual processes aren’t only slow and error-prone but also costly, it might be a smart idea to start here by implementing business process automation software.

Try frevvo’s free trial today to witness the incredible process improvements that automation software provides instantly.