Documented processes standardize how work gets done and improve overall operations. But a process that worked in the past may not be the most efficient today.

Companies grow in complexity as they expand their product line, hire more employees, and adopt new technologies. These changes can cause certain processes to become inefficient over time.

Continuous process improvement is the ongoing effort to ensure processes run effectively in the face of constantly changing business conditions. Companies must have a system to identify and address inefficiencies without disrupting operations.

This is where a process improvement plan comes in — a set of guidelines that help you increase operational efficiency.

In this article, we’ll take a look at what a process improvement plan is, the benefits it offers, and how to create one. We’ll also cover the different methodologies you can follow to implement new changes.

Click the links below to jump straight to the section you want to learn more about:

- What Is a Process Improvement Plan?

- Benefits of a Process Improvement Plan

- How to Create a Process Improvement Plan

- Choosing a Process Improvement Methodology

What Is a Process Improvement Plan?

A process improvement plan is a document that outlines the steps to improve a business process.

It involves mapping existing processes, identifying bottlenecks, and implementing new changes.

A process improvement plan provides guidance on how managers can identify waste and improve the quality of work output. These efforts enable teams to work more productively.

As an example, consider document-centric processes like contract approvals.

Using paper forms may make sense in the early stages of a business, but it can quickly lead to bottlenecks — employees waste time filling out and sending forms to their manager for approval.

This is the exact problem that the Initial Saudi Group faced.

Processing new contracts took up to 10 days, as it involved scanning and sending each one between offices for approval. The lengthy process meant frequent delays on new projects.

Afzal Jandira, Head of Business Systems, was tasked with improving contract approvals.

By following a process improvement plan, Jandira got to the root of the problem and turned to frevvo to set up automated workflows to streamline approvals.

Contracts now only take a few days to complete. Replacing paper forms with dynamic forms and using digital signatures means that employees never lose or misplace paperwork.

This is just one process improvement example. A process improvement plan helps you break down existing processes and uncover ways to make them more efficient.

Let’s look at how a process improvement plan benefits your company.

Benefits of a Process Improvement Plan

Markets are constantly evolving as new technology emerges and competitors expand their product lines. Companies must look for ways to improve their processes to stay relevant.

Here are some of the benefits of an effective process improvement plan and how you can use it to deliver more value to your customers.

More Efficient Operations

Optimizing or removing steps that add little to no value increases overall efficiency. Consider the employee onboarding process.

Having new hires fill out stacks of forms on their first day and providing little guidance is unlikely to leave a positive impression. There’s practically no engagement.

By using onboarding software like frevvo to automate and improve this process, you can engage new hires early on and get them up to speed even faster. In fact, 69% of employees say that automation will allow them to focus more on their primary job duties.

Automation allows you to streamline operations and even reduce the number of steps in a process. This increased productivity has a positive impact on your bottom line.

Higher Employee Engagement

Employees today want to realize their full potential at work. In fact, 9 out of 10 workers are willing to earn less if it means working on more meaningful projects.

Yet, employees spend just 27% of their time on skilled work. They spend the rest of their time on “work about work” activities, like communicating about tasks and hunting down documents.

Having employees spend most of their day on mundane tasks can cause them to feel frustrated with how they’re spending their time. Prolonged frustration can lead to burnout and high turnover rates.

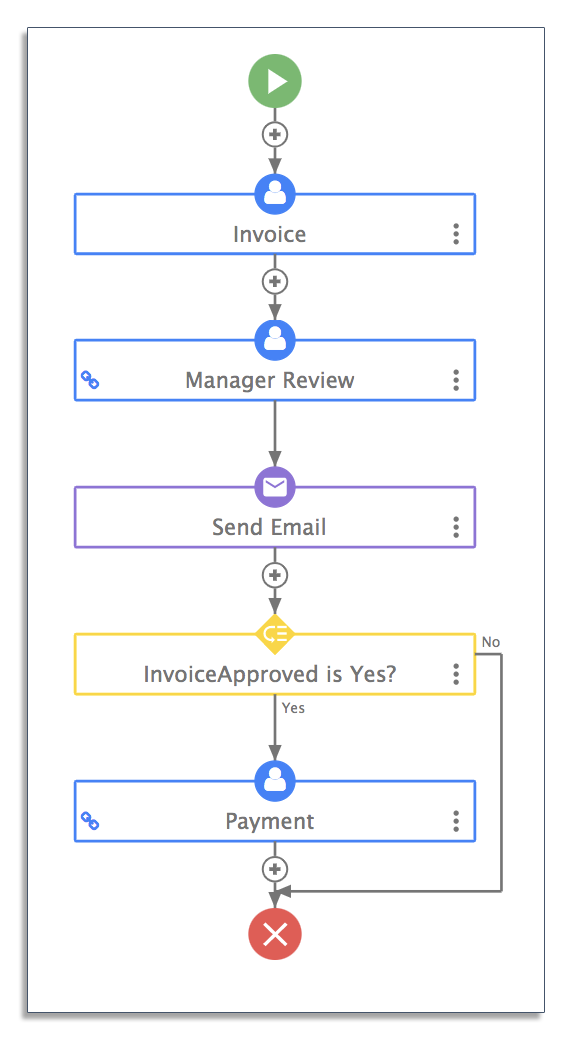

Executing a process improvement plan helps cut down on repetitive tasks. For example, with frevvo you can create automated workflows that route documents to the right approvers.

Here’s an example of a contract approval workflow:

Employees can focus on higher-value work instead of chasing down their managers.

Reduced Risk

Certain tasks are more prone to errors than others. Examples include manual data entry and transferring data from one system to another.

The problem with performing tasks manually is the increased risk of error. An employee may enter the wrong data or make a calculation error. Fixing these mistakes (assuming someone catches them) can be time-consuming and costly.

A process improvement plan can help you identify which parts of a process are prone to error and draw up changes to mitigate them.

Increased Agility

Companies need to be agile to quickly respond to market changes and weather unpredictable circumstances. A process improvement plan helps prepare your business for change.

When the global pandemic hit, companies around the world had to close their offices and let their employees work from home. This meant that most companies had to reexamine their processes and implement new changes to stay afloat.

These included adopting various tools and turning to automation. 63% of small businesses say that automation helped their company quickly pivot due to the pandemic.

Now that you know how a process improvement plan benefits your company, let’s look at how to create one.

How to Create a Process Improvement Plan

Whether you’re a startup or an established company, a process improvement plan ensures your processes are running smoothly. Any flaws in a process, no matter how minor, can turn into bigger issues unless you address them.

Follow these steps to write an effective process improvement plan.

1. Document Existing Processes

For your process improvement plan to work, you need to document existing processes first. This includes mapping a process and writing detailed instructions for each step.

Get feedback from the rest of the team to help with this step. You can also walk through a process yourself to ensure you’re not missing anything.

While you can certainly use pen and paper here, consider using a tool like frevvo for process mapping. The workflow builder enables you to visually map out each step of a process.

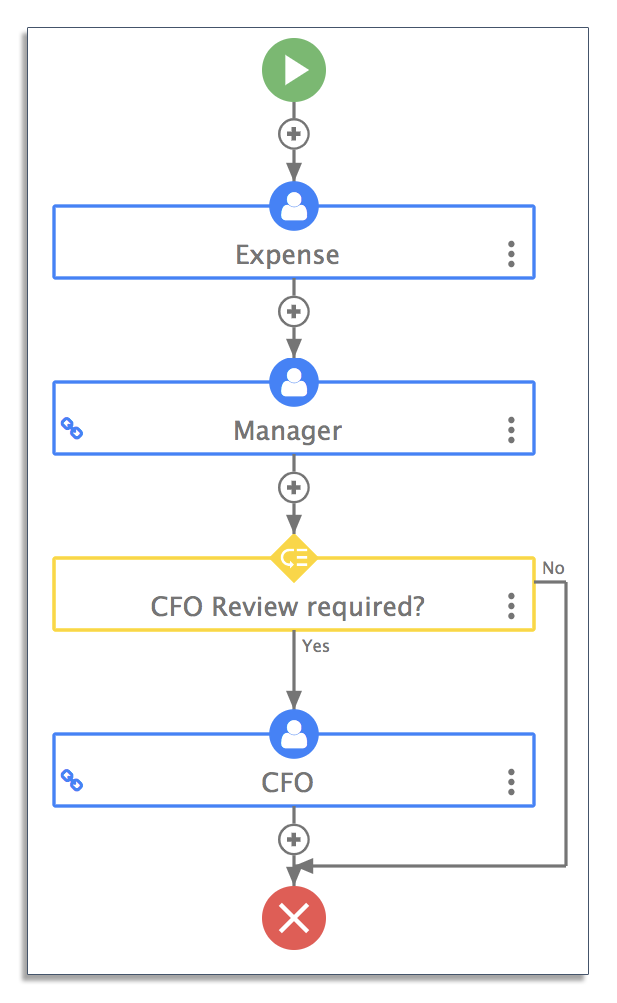

Here’s an example of a process for expense claims:

Breaking down a process like this will make it easier to identify bottlenecks. Then gather data to determine how the process currently performs. This will allow you to establish a baseline that you can compare future results against.

2. Analyze a Process

Now that you’ve mapped out a process, the next step is to analyze it. Take a closer look at each step to identify areas of improvement.

Tracking down the root cause of an issue is crucial here.

As an example, take churn rates — the rate at which customers stop doing business with you.

High churn rates have a direct impact on revenues. Unless you get to the bottom of why customers are leaving, your company’s growth will continue to stagnate.

Likewise, if a process isn’t performing as well as it should, you need to dig deep to track down the problem to its origin.

Ask these questions to get to the root cause of a problem:

- Which steps are causing delays?

- Where do employees and customers get frustrated?

- What steps contribute little to no value?

- What tasks are consuming more resources?

3. Redesign the Process

Work with your team to brainstorm ideas on how to redesign a process. What parts of the process can you trim down or even eliminate? Are there any steps you can automate or tweak to improve output?

Redesign the process based on the insights gathered.

As an example, let’s say that cycle times — the time it takes to complete a process — are unusually long for purchase orders.

An analysis reveals that employees are spending a lot of time just creating them. In this case, you can use a tool like frevvo to digitize your forms and even pull in data from a database.

Here’s an example of how that looks:

Employees can choose a vendor, and the fields will automatically populate, greatly speeding up the document creation process.

4. Acquire Resources

At this point, you should have a redesigned process with input from your team. The next is to acquire the resources you need to implement those changes.

If a bottleneck in a process stems from a backlog of work, you might consider adding more people to the team. That could mean bringing in people from other departments or hiring new workers.

In addition, if you’re turning to automation to streamline certain tasks, make sure you have the process improvement tools you need before you implement your plan.

5. Draft an Implementation Plan

Drafting an implementation plan is like planning a project. It involves assigning roles and establishing schedules to keep things on the right track.

Most importantly, prior planning sets expectations and keeps teams aligned before you make any changes. This increased accountability leads to better outcomes.

Start by assigning tasks to each team member and allocate resources accordingly. Then create a timeline with corresponding start and end dates for each task. Use the process documentation you created earlier to help with this step.

Choosing a Process Improvement Methodology

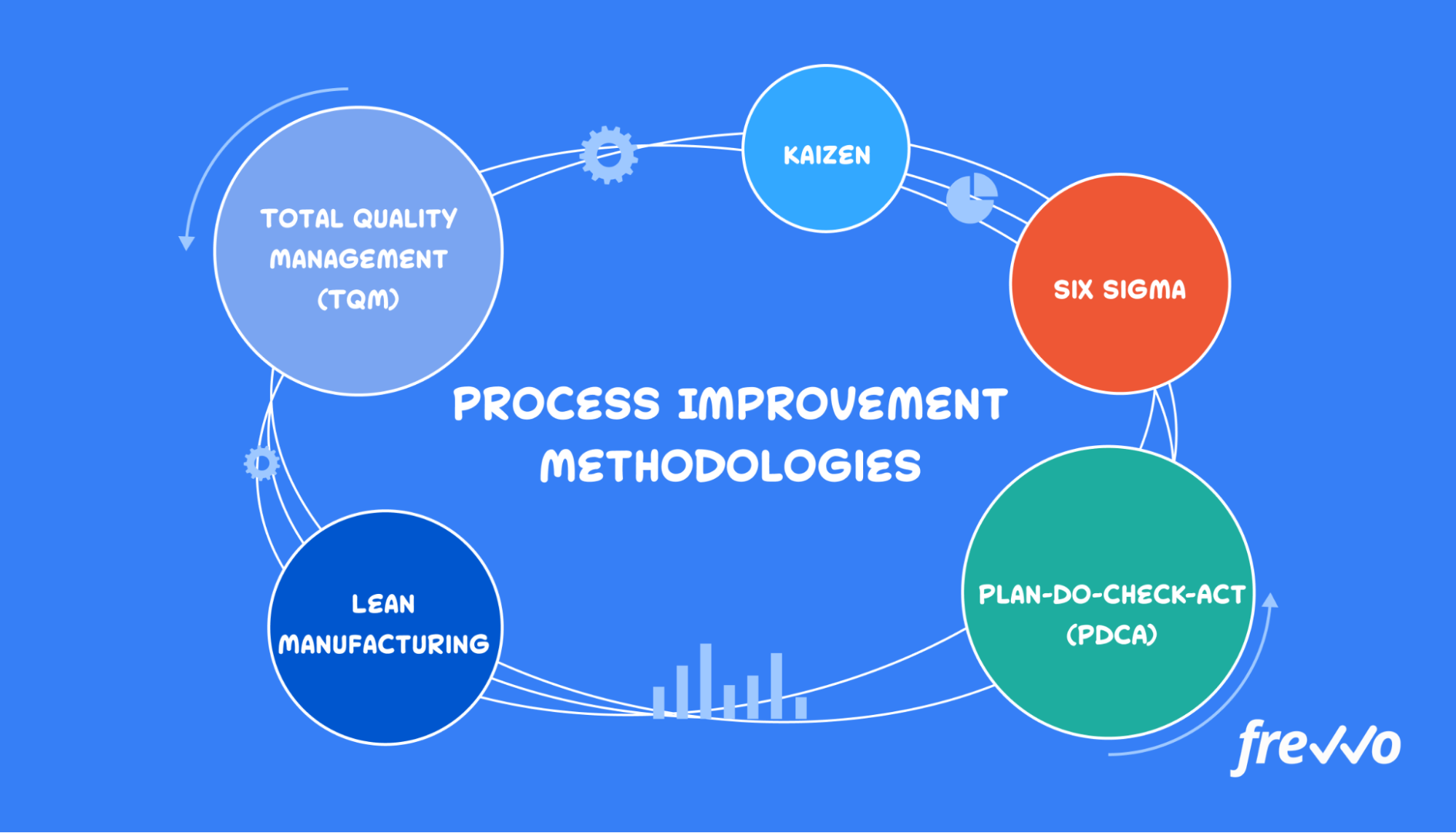

There are several methodologies that you can adopt to carry out improvements and create a new process. These are Six Sigma, lean manufacturing, kaizen, total quality management (TQM), and plan-do-check-act (PDCA).

Let’s take a closer look at each one.

Six Sigma

Six Sigma is a process improvement methodology that began in Motorola and has since spread to other companies.

DMAIC is the improvement cycle for Six Sigma and stands for the following:

- Define: Define a problem you want to solve.

- Measure: Collect data to measure how the process performs.

- Analyze: Analyze the process and identify areas of improvement

- Improve: Develop and implement new solutions.

- Control: Track process improvements and maintain the changes.

Lean Manufacturing

Lean manufacturing is a process methodology that aims to eliminate as much waste as possible without compromising on quality.

A good example of “waste” is the time that employees spend chasing down their managers for approvals. One way to cut down on this type of waste is to use a tool like frevvo to automate document routing and create a digital signature workflow.

Kaizen

Kaizen is a Japanese term that translates to “change for the better” or “continuous improvement.” This methodology focuses on small, incremental changes over time rather than breakthroughs.

A good example is the use of andon cords in Toyota factories. Workers would pull on overhead cords if they discovered a problem. This would stop the assembly line and immediately alert a team leader so they can work on a solution.

Total Quality Management (TQM)

Total quality management, or TQM, is a methodology that seeks to build long-term success through customer satisfaction.

TQM takes a continuous improvement approach to improve processes. It involves employees at all levels working together to reduce waste and increase quality.

Plan-Do-Check-Act (PDCA)

Plan-Do-Check-Act, or PDCA, is an iterative methodology that helps organizations become more efficient. It stands for the following:

- Plan: Analyze a process and plan new changes.

- Do: Implement the changes on a smaller scale.

- Check: Collect data and analyze the results.

- Act: Apply what you learn on a larger scale.

Then you’d simply repeat the PDCA cycle to continue improving business processes.

These process improvement methodologies have their own strengths and weaknesses, so it’s important to carefully consider each one before choosing one.

Start Automating Your Processes

Every organization depends on processes to operate. But any existing process can become inefficient over time and lead to poor performance.

Creating a process improvement plan as laid out here will help you identify bottlenecks and come up with more efficient solutions.

No matter what process you’re looking to improve, it’s important that you have the right process improvement tools.

Start automating your processes with frevvo’s workflow software. With the simple drag-and-drop tools, you can visualize your processes and create powerful automated workflows.

Get started today with a 30-day free trial to test drive the software for yourself.