Despite the importance of business process modeling, nearly half of all organizations fail to model more than 25% of their processes.

Without a business process model to guide them, these organizations are flying blind. They won’t be able to see where bottlenecks are holding up the process or where they can optimize the workflow.

By modeling each business process, you get a feel for every eventuality, helping you to cut back on processing costs, reduce errors in the pipeline, and speed up workflows.

Read on to learn the ins and outs of business process modeling and how it can help you optimize your processes.

Want to jump ahead? Click here:

- What Is Business Process Modeling?

- Why Is Business Process Modeling Important?

- How Can Business Process Modeling Help To Optimize Existing Processes?

- Next Steps After Modeling Your Business Processes

What Is Business Process Modeling?

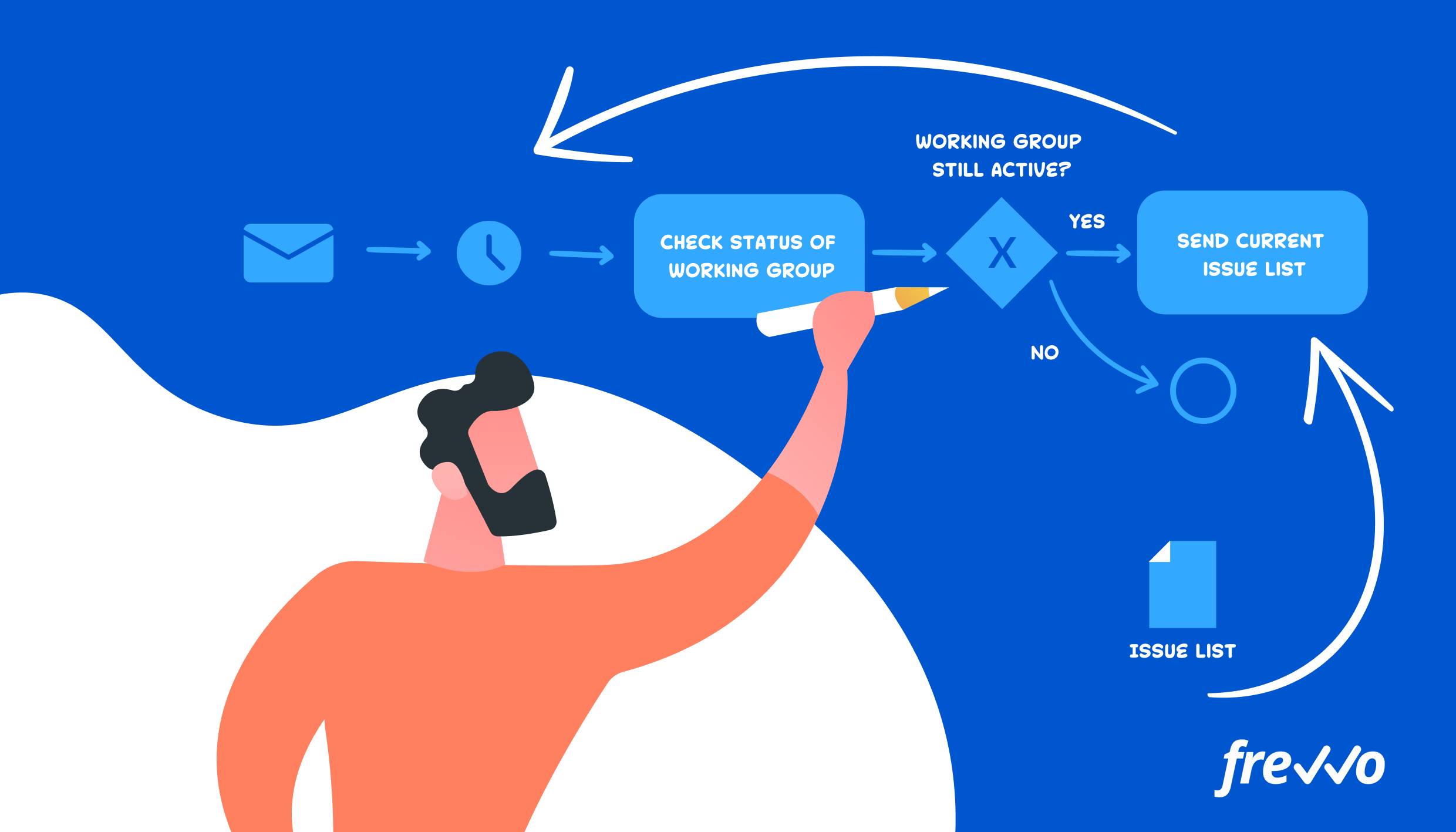

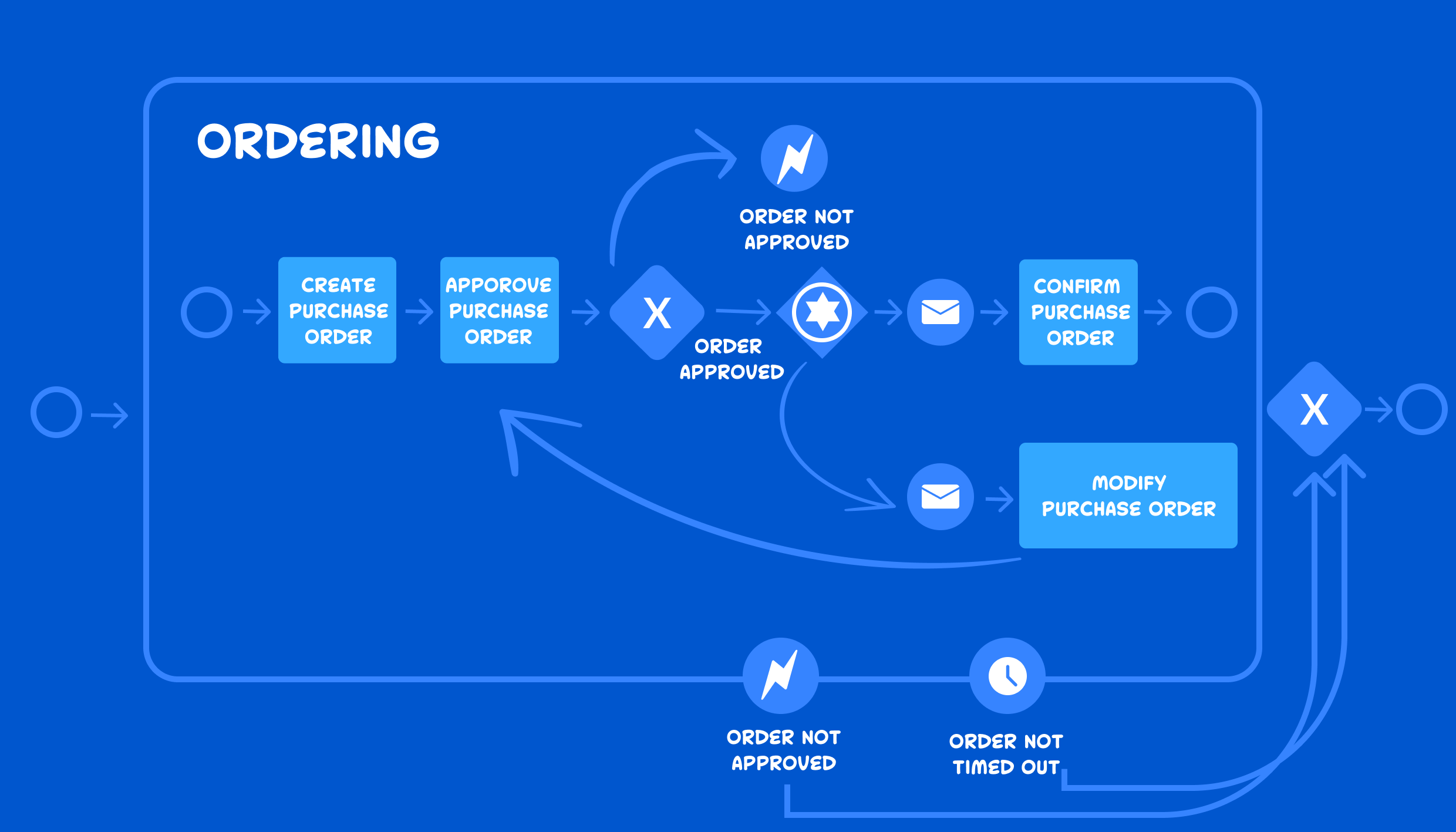

A process model (also called a workflow model) is a graphical representation of a new or current process. Business process (BP) modeling produces a data flow diagram that provides a clear visualization of the sequence flow of business activities, materials, and responsibilities throughout a business process.

Business process modeling can be used to improve an existing process or model a new one. By creating a clear diagram of your process, you’re better able to identify ways to optimize process management, so it runs efficiently and effectively.

Despite these benefits, the majority of businesses model less than half of their processes.

It’s important to recognize that process modeling is different from business process mapping.

Process mapping is far less detailed than BP modeling. A process map can be any form of simple static process activity diagram that shows how a process flows from start to finish. This could be a quick sketch of a flowchart or a series of sticky notes tacked on a whiteboard.

A business process model is far more in-depth. Usually created with a business process modeling tool, a process model shows the flow of activities and which tasks are completed, by who, and when. A process model will also show various conditional paths based on different decisions and may also show the flow of materials.

A business process model will most often be written in the unified modeling language (UML) known as Business Process Model and Notation (BPMN).

By using this UML, a BPMN diagram is widely understood and less likely to confuse. You’d simply train your staff on how to read a UML diagram that uses BPMN. They’d then be able to understand any business process model that’s created within your organization. That way, everyone’s on the same page.

Why Is Business Process Modeling Important?

BP modeling not only helps you to structure a new process, but it’s also an excellent business analysis tool to help you make continuous improvements to existing processes.

According to a recent paper by Lucija Ivančić, an Economics and Business Teacher at University of Zagreb, “Business process modeling is the core of every process improvement or reengineering initiative[…] It can be used in business process improvement initiatives aiming to detect different process irregularities whose detection and elimination contribute to the business excellence.”

A business process diagram breaks down a workflow into its individual components, so you can see how it performs at each stage.

This enables you to clearly see where you can make improvements to the process and clarifies how and when each task should be completed.

It then becomes easier to train your team as you’re better able to communicate your business strategy and ensure that process execution aligns with it. With a defined step-by-step process map in place, employees follow the same workflow each time, resulting in consistent outcomes.

In this sense, a BPMN diagram provides a common language for everyone to understand how processes should be carried out.

How Can Business Process Modeling Help Optimize Existing Processes?

While a business process model is an incredible tool that can help you visualize all the task data involved with building processes, it’s also a top way to map process improvement for an existing process.

Here’s why you should use BP modeling to optimize current processes.

1. Identify Common Errors

By modeling each workflow, you’ll begin to identify the most common errors.

Process modeling will identify the most frequent errors and show you the types of errors you’re making, which helps devise an appropriate solution.

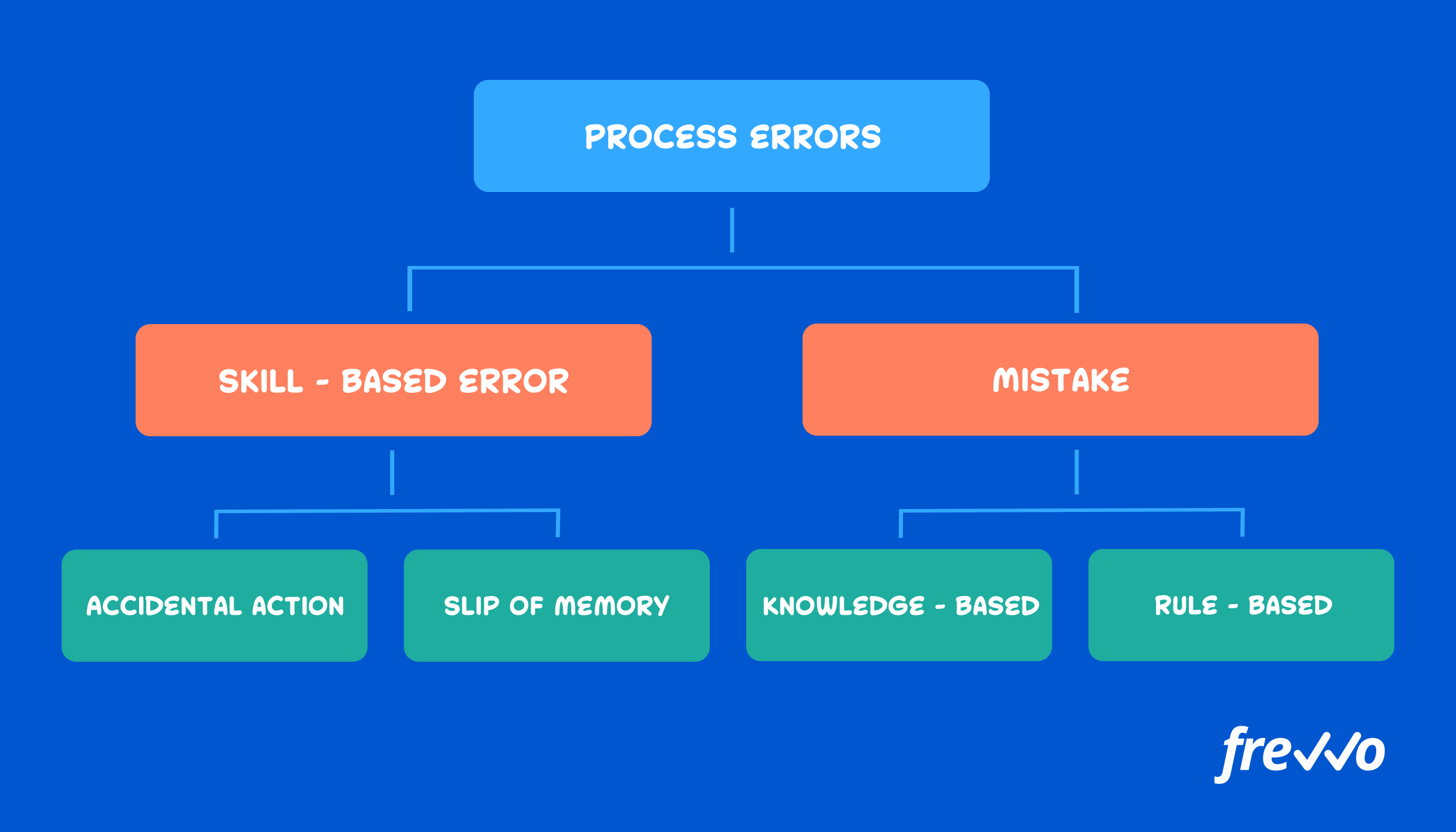

There are two main types of process errors that commonly occur: skill-based errors and mistakes.

Skill-based errors are the first big issue.

These occur when the person carrying out the process has the skill to perform the task and knows how to do it, but they either have a memory lapse (like forgetting one of the steps) or a slip of action (like turning on the wrong switch).

These errors can be addressed through process automation.

When humans repeatedly complete mundane, repetitive tasks, they eventually get bored, and their mind wanders, leading to skill-based errors. Process automation can help reduce the human labor involved in repetitive tasks, in turn cutting back on errors. In fact, half of business leaders and employees believe that fewer errors occur with process automation in place.

Take the logistics firm Hellman, for example.

Previously, Hellman had been using paper and PDF forms for crucial processes, such as contract amendment and new customer credit approvals. These paper processes were inefficient and repeated mistakes were leading to misallocated costs and severe pipeline delays.

By implementing frevvo, Hellman was able to automate these processes. This prevented duplicate data and repeated errors that were associated with manual task management.

Mistakes are the second type of error.

There are two types of mistakes: rule-based and knowledge-based.

Rule-based mistakes happen when the person doing the task misapplies a rule or doesn’t apply the right rule.

Knowledge-based mistakes occur when someone doesn’t have the right knowledge or skills to complete the task at hand.

Both of these types of errors can be fixed with better training.

2. Pinpoint Speed Issues and Process Delays

If you notice that a current process is slow or prone to delay, create a process model to identify the bottlenecks causing speed issues.

By modeling the process, you’ll be able to identify common delays. Is paperwork often held up in one place? Is there a particular task that can only be carried out by one person? Is there a specific machine that’s overloaded? Is there a common mistake that holds up the line as it continuously needs rectifying?

The problem is that delays don’t just slow down one process; they have a knock-on effect further down the line. This can lead to extra costs in labor hours to get the process back on track.

You’ll often find that delays are caused by manual process management. Not only is manual processing slow and labor-intensive, but it’s also error-prone, which causes further delays.

According to 42% of business leaders, process automation can speed up repetitive task completion. In fact, 78% of business leaders agree that their staff could save up to 60 hours every month with process automation in place.

Look at Yves Rocher, for instance.

During peak season, the beauty retailer doubled its staff size. However, slow manual onboarding processes meant that many people would often start working without payroll being processed.

By switching to frevvo’s process automation tool, Yves Rocher’s onboarding workflow is now much faster. Auto-population and auto-validation of forms mean faster data entry and fewer mistakes. Automatic routing means applications are processed in no time.

3. Boost The Quality of Process Outputs

35% of companies say that they’re working on optimizing internal processes to improve their end product.

If the quality of your end products isn’t up to scratch, it’s time to evaluate the workflow to see what’s affecting the standards.

You may find that you’re not spending enough money on the process, so there isn’t sufficient staff to ensure high quality, or you’re stuck using poor materials.

Alternatively, you may be carrying out the process too quickly, leading to lots of errors and not enough time for quality assurance.

Remember, poor quality outputs can result in serious reputational damage.

Not only can poor quality affect customer satisfaction with your goods and services, but it can also jeopardize supplier relationships. Likewise, if one team isn’t producing good enough outputs, it can affect the ability of the next person to start the follow-on process.

4. Increase Staff Productivity

Staff can be expensive if they’re not productive. That’s why seven out of 10 organizations are working on processes to reduce costs and maximize productivity.

Not only will higher productivity reduce the cost per staff member, but it also increases the speed of your processes, enabling you to scale your production.

By modeling each business process, you can see where staff are performing slowly and ineffectively.

If there are tasks that result in continuous errors or that take a long time to complete, your productivity levels decline. You need to focus on improving these issues to boost productivity.

Digitizing and automating processes can certainly help to improve productivity.

5. Reduce Excess Workflow Processing Costs

BP modeling helps to identify excess costs in the workflow. By creating a diagram of each business process, you can see unnecessary waste, costs for remedial work, expensive materials, and high labor costs.

Since overspending eats into your profits, it’s in your best interest to use a business process diagram to work out where you can save money and optimize processing.

One major way to cut back costs is to introduce process automation. According to 31% of business leaders, automation reduces labor costs by cutting out the long hours dedicated to manual processing.

Take La Cité, for example.

Manual student registrations required staff to check the accuracy of each student registration form manually.

By switching to frevvo’s business process automation software, students now complete registration online. Registration forms are automatically validated online, so the college no longer has to pay staff to check the information manually.

6. Improve Supplier Relationships

Supplier relationships are integral to the stability of many organizations. In fact, 47% of organizations agree that improving supplier relationships is the most effective method of preventing supply chain bottlenecks. Additionally, 56% claim that better communication with suppliers helps to spot potential issues early.

Not only will unhappy suppliers fail to prioritize your company, but poor working relationships can result in losing important vendors.

Use business process modeling as a way to spot inefficiencies within your supplier relationships. You may notice delays in paperwork sent to the supplier or errors in the documentation. Slow payments are also an issue, as is poor communication and non-transparent processing.

By creating a clear business process model, you’ll get a better idea of how you can improve supplier communication. Perhaps you could digitize documentation, so you have a better audit trail. Or maybe you could automate payments so that suppliers receive remittance quicker.

Next Steps After Modeling Your Business Processes

Once you’ve modeled your process, you either need to build out the new process or work out how to implement improvements to an existing one.

Use the Plan, Do, Check, Act (PDCA) technique to implement new processes and create changes on a small level to see if they work before scaling them up.

In the first two steps, you plan the new process or process change and then implement it. In the third stage, you monitor the implementation to ensure that it’s performing the way you want it to. In the last stage, you act by either scaling up the new implementation or by making adjustments if it’s not performing effectively.

Process automation should be a priority, as it enables you to scale processing by cutting back on manual labor, resulting in fewer errors, lower costs, and faster processing.

In fact, 78% of business leaders believe that automating tasks in the organization increases productivity for all, and 73% believe that automation can help reduce costs through better staff utilization.

In terms of overall business growth, 80% of business leaders believe that automation can propel their companies forward, while 67% agree that automation gives their organization an edge over the competition.

That’s why organizations like Cricket Australia switch to frevvo.

Previously, manual invoice processes took four days to complete. By using frevvo to automate the process, Cricket Australia has now managed to half this turnaround time.

Optimize Workflows By Modeling Processes

Business process modeling is a major part of optimizing your workflows. By modeling the process, you can pinpoint bottlenecks and identify improvement opportunities to streamline workflows, reduce costs, and speed up processing.

Remember, it’s important to find the right business process management tools to help you create effective business process models and automate them for optimal efficiency.

If you’re looking for a business process automation tool that’s affordable and simple to use, give frevvo’s free trial a chance now.