What Is Multi-Sourcing?

Sourcing the raw materials, components, products, and outsourced services needed to conduct your business is a core part of any organization’s operations.

While some business owners would argue that a smaller pool of vendors translates to better terms, service and more personal attention pricing, a growing number of businesses are making a strategic shift away from single-source supplier agreements in response to global events that threaten to disrupt supply lines or raise costs. As a result, multi-sourcing is gaining popularity as a procurement model.

Driven by organizations that seek to mitigate risk as well as businesses that seek more flexible, innovative and competitive supplier relationships, multi-sourcing offers a number of attractive advantages.

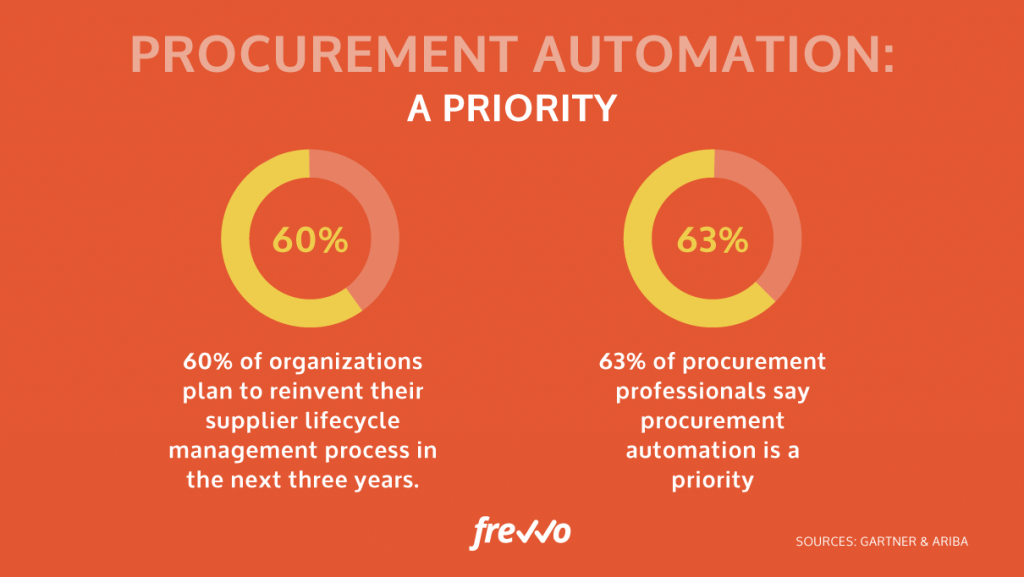

However, multi-sourcing can increase the complexity of managing suppliers. Procurement process automation, where you digitize and replace manual workflows with electronic ones, can make a huge difference in managing this added complexity allowing you to reap the full benefits of multi-sourcing.

Want to jump ahead? Click here:

- What Is Multi-sourcing?

- Why Does Multi-Sourcing Matter?

- Don’t Ignore Supplier Diversity

- Supplier Lifecycle Management Steps

- Automation for Effective Multi-sourced Supplier Management

Why Does Multi-Sourcing Matter?

Let’s take a closer look at the advantages of multisourcing:

- A larger pool of vendors or more segmented outsourcing can reduce the risk of supply shocks (disasters, trade embargos, tariff escalations, resource or component shortages, plant fires, financial setbacks) impacting your operations and prices.

- A more diverse supplier base also means you’re less dependent on any individual supplier and can spur competitive pricing among vendors.

- It can be risky to “put all your eggs in one basket” and your customers may, in turn, find it risky doing business with you if they know that you single-source.

- When using a single vendor for large and complex deals (for instance, IT outsourcing) you find yourself “locked-in” because of specific dependencies, which can make it difficult to negotiate for better prices, affecting your ability to remain competitive.

- A shortage of a single-sourced material might hit you harder than if you deal with multiple suppliers.

- Single-sourcing can cause the dependence balance to shift out of your favor, with you becoming more dependent on your supplier for materials than they are on your business. This puts you at a disadvantage when renegotiating prices and terms.

- Multi-sourcing allows you to monitor which suppliers perform best, allowing you to make better, more informed deals in the future.

Don’t Ignore Supplier Diversity

Making diversity and inclusion one of your key supplier selection criteria has business benefits over and above the social good you do by supporting minority business owners and injecting money into historically disadvantaged and underrepresented communities.

According to The Hackett Group’s ROI-Related Supplier Diversity report, companies that engage in long-term supplier diversity programs generate a 133% higher ROI than businesses that don’t. Moreover, for every $1 million spent on procurement costs, supplier diversity programs return an additional $3.6 million.

Supplier Lifecycle Management Steps

For all its benefits, multi-sourcing has a drawback: it dramatically increases the complexity of supplier management. As a result, businesses seeking to embrace multisourcing need to rethink which resources they allocate to the critical task of supplier lifecycle management and how they can make this part of their operations more efficient.

Relying on manual workflows to orchestrate supplier management would be a mistake in a multi-sourcing model. Aside from the vast quantity of data that needs to be managed meticulously, managing the supplier lifecycle manually impairs your ability to analyze data, and bogs your procurement and finance teams down in tasks like approving and paying invoices when they could be focusing on more strategic tasks like relationship management, risk analysis and supplier development.

With automation, you can unlock the full potential of your supplier contracts, build robust vendor qualification, onboarding and evaluation processes, and gain far greater insight into your spending.

Let’s look at the steps involved in a typical supplier lifecycle:

1. Qualification

Qualification is the first step in the supplier management process. In a nutshell, it’s your application process. Even if you approached the supplier and not the other way around, it’s essential that you evaluate whether prospective suppliers live up to your expectations and will be able to deliver the material, product or service you wish to procure at a satisfactory standard. At this stage, you might use an application form to help you with the first round of vetting, and you might apply automation to automatically cull applications that aren’t relevant to your requirements.

2. Evaluation & Risk Assessment

The evaluation stage is an extension of the qualification stage. Once you have a smaller pool of candidates, you will want to measure them against a number of metrics, including quality, total spend, supply risk, customer reviews, location, profitability, performance, labor practices, innovation, sustainability, diversity and whatever other factors matter to you as an organization. You can assign each supplier a score for each metric to determine which suppliers are the best fit.

3. Selection & Segmentation

During the selection stage, you make your decision and notify the supplier(s) you have chosen that they have met your criteria. Next, you’ll segment/rank your suppliers into categories according to your assessment in the previous stage. This way, if something happens to prevent your first choice from delivering, you’ve got a backup plan—or three.

4. Onboarding and Information Management

Supplier onboarding is the stage during which you collect all the information and documents you need in order to add a vendor to your approved vendor list (AVL). You can apply workflow automation to help you collect, capture, store and manage all supplier data in a way that makes it easy to conduct your business with them and to run analytics to manage their performance and compare it to that of other vendors.

5. Performance Management

It’s important that you continue to evaluate and monitor your vendor’s performance to determine whether they are meeting the terms of your agreement. Metrics might include quality, price, delivery time, frequency of supply interruptions/late deliveries, customer service and more.

6. Supplier Development

Truly successful supplier relationships are set apart by a high degree of collaboration.Businesses with strong collaborative relationships with their suppliers grow twice as fast as their counterparts who ignore vendor collaboration. Supplier collaboration includes active process and product/service optimization and development and requires frequent and candid constructive feedback.

7. Ongoing Risk Management

It’s vital that businesses conduct ongoing risk assessment and risk mitigation for each of their key vendors throughout the supplier relationship to ensure that supply shocks don’t catch them off guard. Having a contingency plan (such as a backup supplier or multi-supplier model) in place is critical to preventing loss of business in the event of a disaster.

8. Relationship Management

Cultivating strong long-term relationships with your key strategic vendors can have significant return on investment. By fostering loyalty among your suppliers, you prepare your organization for the future. You never know when you might need to call in a favor or place an order on short notice, and vendors who know and trust you are far more likely to be obliging.

Automation for Effective Multi-sourced Supplier Management

For successful multi-sourcing, you’ll need detailed service level agreements outlining individual suppliers’ responsibilities to ensure that there are no gaps or overlap between vendors. You’ll also need to ensure that contracts are updated regularly to reflect changing business conditions and new service components. With multiple vendors, the various contracts also need to be kept in sync with one another to avoid redundancy and conflicts of interest.

As you’ve seen in the section above, automation can streamline and simplify your supplier lifecycle management considerably, saving you valuable time and money. Let automation do the heavy lifting when it comes to data entry, order management and tracking, freeing up your procurement and finance teams to focus on relationship building and strategy.

Here are some ways procurement automation software like frevvo can help you implement a successful multi-sourcing procurement strategy:

- Using dynamic digital forms speeds up the process of capturing supplier data and reduces data entry requirements. Digital forms can also be linked to SQL databases to automatically update information on the fly and even auto-populate known fields in forms.

- Creating your own custom forms and conditional routing workflows using frevvo’s 100% visual drag-and-drop wizards, you can automate much of your supplier vetting process to align with your policies and priorities.

- Electronic signatures make it easy to sign contracts and manage purchase order approval workflows, and allow managers to sign forms on-the-go using mobile devices.

- Automating your finance processes such as accounts payable makes for better supplier relationships (and allows you to take advantage of early payment discounts).

- Automation gives you access to rich business intelligence data, allowing you to apply AI analyses to your supplier data to identify risks and inefficiencies as well as opportunities.

Ready to simplify your procurement processes and embrace multiple sourcing as a supplier strategy? Try frevvo’s workflow automation software absolutely free of charge for 30 days. Want to learn more about how automation can streamline your procurement processes first? Download our ebook to find out more.