Since COVID-19 swept the world, there have been unprecedented interruptions to global supply chains. Prioritizing resilient procurement processes has never beeAs organizations are rapidly moving to digital, data-driven environments, it’s wise to migrate purchasing and procurn more crucial in the face of economic collapse.

Where cost control was previously the most important item on the procurement agenda, now your main procurement goal should relate to business resilience. Ethical practices, risk mitigation, and cybersecurity are more significant than ever.

It’s time to throw out clunky, old-fashioned manual procurement operations and replace them for streamlined automated procurement processes.

Why? Because through digitization, standardization, and automation, you’ll be able to keep a closer eye on the risks and responsibilities along your supply chains.

This results in more resilient procurement processes that keep your business thriving.

Need a better idea on where your purchasing department should be focusing its attention?

Read on for the top procurement goals that will keep your business flourishing in an unpredictable world

Want to jump ahead? Click here:

- Cost Control — A Waning Procurement Priority

- 6 Critical Procurement Goals for Creating a Resilient Business

- Changing Priorities for a Changing World

Cost Control — A Waning Procurement Priority

Traditionally, procurement’s main goal has been low costs.

It’s still the top priority but its importance is waning. According to a recent survey, the number of procurement managers who consider cost control as their top priority fell from 82% to 72%.

Obviously, procurement managers are focusing on other, more strategic aspects of procurement.

As Olivier Joseph, Senior Procurement Engagement Manager at Microsoft, explains it: “Although cost control is still the main priority at Microsoft, it is now one of seven top metrics that are all equally important.”

If cost control is no longer as important as it once was, what other procurement priorities are clinching that top spot?

Here are six procurement concerns that your procurement manager should be taking into account for more resilient supply chain management.

6 Critical Procurement Goals for Creating a Resilient Business

While cost control continues to be important, other priorities are having an impact on procurement goals within companies worldwide.

Ethics, risk management, and efficiency are now hyper-significant when choosing suppliers. These factors shape the face of the business in the eyes of the consumer and help to provide operational resilience.

Here are the top six priorities you should be focusing on to meet your procurement goals in the modern digital age.

1. Corporate Social Responsibility (CSR)

It’s the era of responsible social practices and customers are holding companies accountable for unethical behavior.

In 2018, more CEOs were fired over unethical conduct than poor financial performance, showing just how important corporate social responsibility (CSR) has become.

Today, customers champion businesses they perceive to be ethical and denounce those using disreputable practices.

Consider that nearly 10% of a company’s market cap that’s attributable to reputation relies on social responsibility. If your company runs on poor ethical practices, this can have a detrimental effect on its overall value.

Unethical procurement practices, such as sweatshop manufacturing and unsustainable resource extraction, quickly erode trust in a company’s ability to perform.

Take sustainable procurement, for example.

For 61% of consumers, clear sustainable procurement practices are expected. If you’re not using greener methods and your competitors are, customers will go elsewhere.

Companies now have no choice but to respond to customer pressure. A third of firms claim that the demands for more sustainable practices are driving their business strategies.

It’s clear that companies are beginning to accept that they’re fully responsible for the products they sell — from sourcing to manufacture to distribution to support.

If you want to stay in business, you need to pivot your procurement strategies to toe the ethical line — or customers will seek more socially responsible brands.

This means vetting suppliers and contractors to make sure they uphold your company’s ethical values.

It’s also important to share standards with suppliers, perhaps via a formal supplier code of conduct. That way, they understand the moral, ethical, environmental, and labor standards that your company expects.

2. Supplier Reliability

40% of businesses say delivering goods and services on time, every time is the most crucial element in customer satisfaction. In this respect, it’s imperative that you have dependable suppliers who deliver quality goods on schedule.

Otherwise, projects stall, product rollouts are delayed, and customers are left disappointed. Missed timelines often result in investors punishing the stock price for public companies.

Right now, it’s harder than ever to find reliable suppliers. The COVID pandemic has caused such unprecedented supply chain disruption that many small businesses have had no choice but to close their doors.

For 64% of companies, supply chain disruption has been the biggest challenge during the pandemic. 62% of these companies cite logistics disruption as the worst problem, while 52% identify manufacturing disruption as their weak link.

Since companies can no longer rely on their existing vendors, 56% have had to switch to a different vendor or manufacturer.

With this in mind, it’s smart to create alternative procurement plans to make sure goods are delivered on time. This might mean finding a back-up supplier or solidifying arrangements with your existing supplier to guarantee you’re top of the delivery list.

59% of procurement managers have taken measures to strengthen the quality of each supplier relationship in an attempt to make sure their deliveries are first in line.

As globalization spreads out and the pandemic shows no signs of shifting, finding reliable suppliers and managing the supplier relationship has become a top procurement goal.

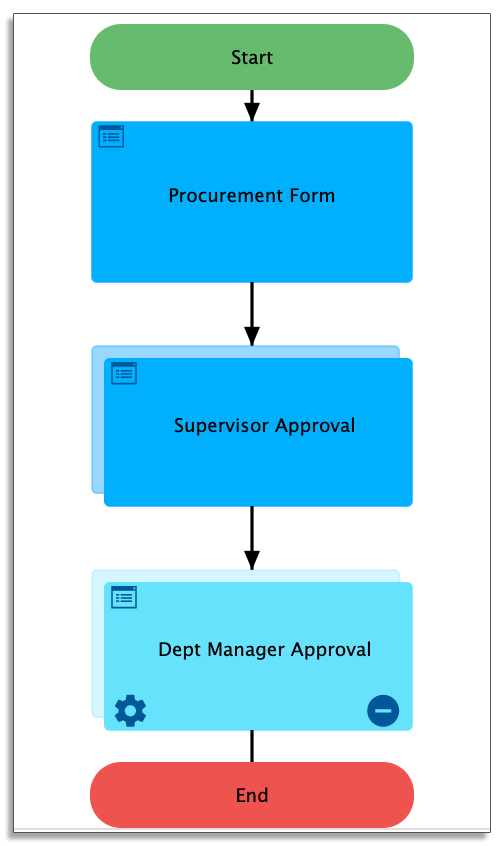

3. Procurement Process Automation

Purchase requisitions, purchase orders, invoice approvals are all simple, transactional processes under the procurement umbrella. Far too often, these processes are manual and are based on emailing Excel documents around.

Email has many issues and hampers your operational efficiency. Yet, the most harmful, long-term effect is that it locks up your proprietary business data.

That data sits in SharePoint repositories, document management systems, or folders. You cannot analyze it — certainly not in real-time — or build models that can learn from it and optimize operations.

While manual processing still plagues most companies, there is a solution. High-performing procurement automation software, like frevvo, can cut out errors, speed up processing, and reduce associated costs.

Despite its existence, however, 52% of Chief Procurement Officers (CPOs) say that the underuse of automation technology in purchasing and procurement is one of the most pressing problems that needs to be fixed.

And everyone’s in agreement.

54% of employees are sure they could cut back 240 hours of wasted time each year by using automation technology, while 48% believe it will help prevent errors.

As organizations are rapidly moving to digital, data-driven environments, it’s wise to migrate purchasing and procurement processes too. That’s why automating these processes and digitizing associated data has quickly become one of the highest procurement priorities of today.

Want to automate your procurement processes?

Quickly automate your workflows using frevvo’s simple, drag-and-drop tools.

Try it free for 30 days.

4. Risk Mitigation

To increase profit, every business wants to buy goods and services at the lowest possible cost, in the least possible time, under the most favorable payment terms possible.

But, this should never be at the expense of stability.

After all, poor risk management can collapse a business. If you’re unable to gauge your supplier’s performance, 64% of procurement professionals agree that this is a major risk.

That’s why half of procurement staff agree that it’s critical to explore supply base risks that might not be immediately obvious from the outset.

Given the inherent risks in the procurement process, it’s crucial for CPOs to have a comprehensive and proactive approach to risk management.

An effective risk management strategy is a planned and systematic process that:

- Identifies the risks

- Assesses their likelihood and impact

- Addresses and controls these risks

- Continuously monitors to identify new risks

5. Talent Management

A recent DHL Research Brief entitled The Supply Chain Talent Shortage: From Gap to Crisis warns of severe talent shortages and estimates that demand for supply chain professionals exceeds supply by a ratio of 6:1 and could be as high as 9:1.

The US Bureau of Labor Statistics reports that jobs in logistics are estimated to grow by 26% through 2020. But that won’t be enough to fill the forecasted gap.

DHL’s brief also explains that the most important factor is changing job requirements.

The ideal employee has both tactical/operational expertise, analytical skills, strategic thinking, leadership and innovation. Unsurprisingly, 58% of companies find it hard to find people with all these skills.

Yet, one third of companies have taken no steps to create or feed their future talent pipeline.

Talent acquisition and retention will continue to be a major challenge and priority for procurement departments in the foreseeable future.

6. Cybersecurity

In today’s digital world, cyber threats are a real risk to supply chain management. In recent years cybersecurity supply chain attacks have risen by 150%.

The problem is that most companies aren’t doing enough to mitigate the risks of a cybersecurity attack, with most firms only employing a perimeter-defense method. This is no longer enough to keep out a hacker.

As Stuart Madnick, a founding director of Cybersecurity at MIT Sloan puts it “The thing they [CPOs] aren’t thinking about are people who somehow, one way or another, can slide right in. Because once you’ve slid in, then all those perimeter defenses are next to useless.”

Take shipping giant, A.P. Møller-Maersk, for example.

International operations ground to a standstill after a powerful piece of ransomware, called NotPetya, managed to enter the firm’s system.

Hackers didn’t enter A.P. Møller-Maersk directly. The shipping company brought in the ransomware themselves by installing an infected piece of accounting software in one of their smaller offices in Ukraine.

A tiny software company called Linkos Group created the accounting program. The ransomware infiltrated the software firm, hijacking its update servers to reach the company’s wider customer base. One of these customers was A.P. Møller-Maersk.

That’s how most supply chain attacks happen — hackers come in through less secure firewalls of smaller companies further down the supply chain.

For procurement departments looking to prevent supply chain attacks, it’s important to consider the following weak points in the procurement process:

- Have any of your suppliers merged or acquired smaller companies who have poorer security?

- Where’s your procurement data being routed? Are these network services secure?

- Are there hidden backdoors embedded in software you’re using?

- Are you using outside contractors? If so, what’s their security like?

If you’re looking for a highly secure procurement solution, try frevvo. Our multi-layered approach guarantees that all your data is tightly secured and we’re constantly updating our systems to improve security across every aspect of the technology.

Changing Priorities for a Changing World

Procurement priorities used to be simple — a laser focus on cost control.

Nowadays, things have changed. Businesses have become far more complex thanks to globalization, social responsibility, talent shortages, and cybersecurity risk. Procurement priorities have changed to meet these challenges head on.

When considering procurement priorities, organizations need to think beyond the bottom line.

Disruptions to global supply chains and cybersecurity concerns pose huge risks to the stability of business worldwide. As a result, procurement departments must implement strategic risk management systems to keep these threats at bay.

What’s more, customers will no longer stand for irresponsible business practices.

The increased scrutiny of labor practices, sustainability, and environmental means that companies who fail to adhere to ethical practices are at risk of losing customers.

It’s your responsibility to make sure all stages of the procurement process uphold these high virtues or you run the risk of corporate scandal.

Of course, none of this is possible without prioritizing talent. The talent wars are real and shortages are likely to continue for the foreseeable future. Acquiring and keeping the best employees is an organization-wide priority — and procurement is no exception.

And perhaps most importantly, efficiency has become more important than ever. Automating your procurement process is the most effective way to speed up these operations and cut out processing errors.

If you want to prioritize efficiency and eradicate inconsistencies in your procurement processes, try a free 30-day trial of frevvo today. You’ll quickly be able to iron out bottlenecks for faster, more reliable procurement in an ever-changing world.